Call (844) 787-4348

That's 844-PURGE-IT

UL LISTED TYPE Y & Z ENCLOSURE PRESSURIZATION SYSTEMS

Product Accessories

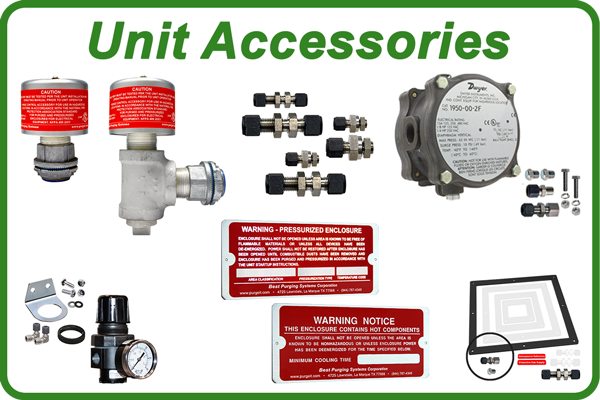

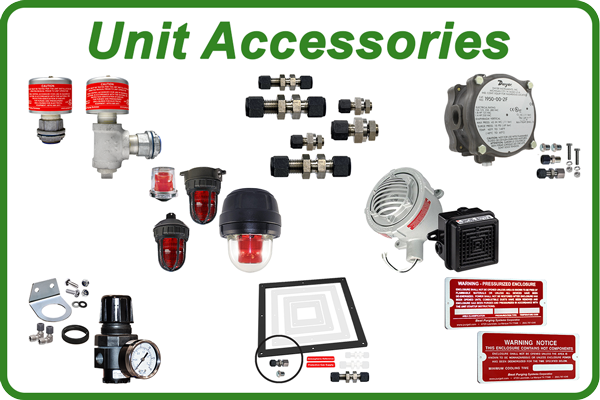

Our Pressurization Unit Accessories simplify installation tasks, ensure total compliance with NFPA 496 safety and labeling requirements, and provide methods to activate and sound alarms that notify local or remote operators upon loss of safe enclosure pressure!

Simply click any item below for the data you require, and feel free to call us if you have any questions.Please also note all data below is provided in our Technical Bulletins for your convenience.

Click any item for more information…

Best Purging Systems Corporation provides these accessories to simplify the process of installation. When purchased with a Unit, installers receive everything they need to quickly install

a unit and eliminate the need to

source other materials!

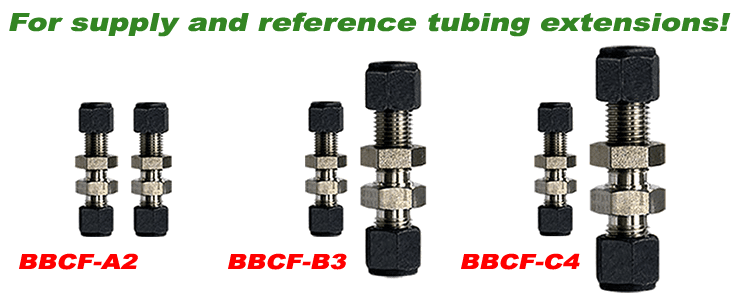

Each fitting kit is intended to facilitate a specific type of connection, depending on whether tubing must be extended inside the protected enclosure, while the pipe connectors are intended to join multiple protected enclosure arrays. Call us or review our Technical Bulletin

for more details!

Best Purging Systems Corporation provides all necessary fittings to complete your installation easily!

Model BBCF

Bulkhead Union Supply & Reference

Provides connections for a protected enclosure to extend

supply and reference tubing inside the enclosure.

| BBCF-A2: | One (1) each 1/4″ Supply & 1/4″ Reference – for Model 101A |

| BBCF-B3: | One (1) each 3/8″ Supply & 1/4″ Reference – for Model 101B |

| BBCF-C4: | One (1) each 1/2″ Supply & 1/4″ Reference – for Model 101C |

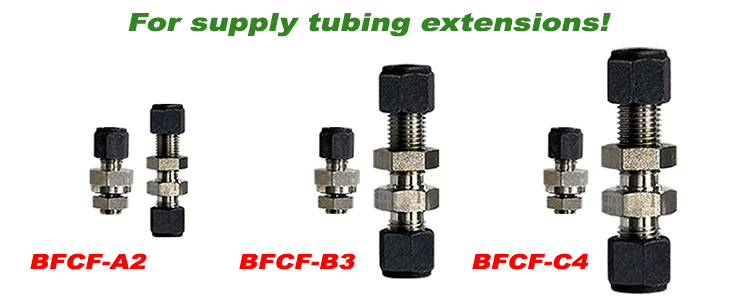

Model BFCF

Bulkhead Union Supply & Flush Mount Reference

Provides connections for a protected enclosure to extend supply tubing

inside the enclosure and terminate reference tubing at the bulkhead.

| BFCF-A2: | One (1) each 1/4″ Supply & 1/4″ Reference – for Model 101A |

| BFCF-B3: | One (1) each 3/8″ Supply & 1/4″ Reference – for Model 101B |

| BFCF-C4: | One (1) each 1/2″ Supply & 1/4″ Reference – for Model 101C |

Model FFCF

Flush Mount Supply & Reference

Provides connections for a protected enclosure to terminate supply and reference tubing at the enclosure bulkhead.

| FFCF-A2: | One (1) each 1/4″ Supply & 1/4″ Reference – for Model 101A |

| FFCF-B3: | One (1) each 3/8″ Supply & 1/4″ Reference – for Model 101B |

| FFCF-C4: | One (1) each 1/2″ Supply & 1/4″ Reference – for Model 101C |

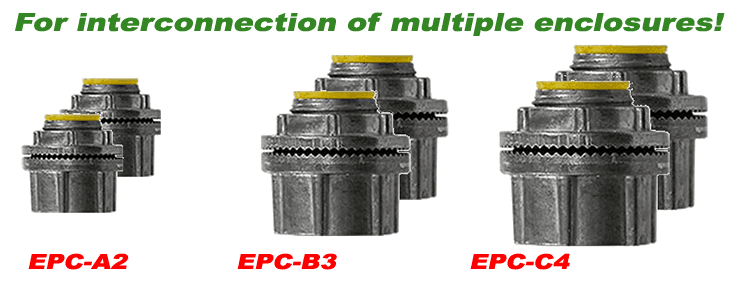

Model EPC

Multiple Enclosure Interconnection Pipe Fittings

Provides Sealed NPT threaded fittings to install pipe connections between two protected enclosures.Additional kits can be utilized for each additional protected enclosure.

| EPC-A2: | Two (2) 3/4″ Pipe Connectors – for Model 101A |

| EPC-B3: | Two (2) 1 1/4″ Pipe Connectors – for Model 101B |

| EPC-C4: | Two (2) 1 1/2″ Pipe Connectors – for Model 101C |

Model FFCF, BFCF, BBCF and EPC Fittings are provided to connect your enclosure purging or pressurization unit to your protected enclosure and to interconnect multiple enclosures in any array.As listed, each kit provides for specific forms of connection.In most cases, it is only necessary to connect tubing between a unit and protected enclosure making the FFCF Kits ideal.In other circumstances, it may be essential to route either supply or reference tubing to other locations within a protected enclosure, which can be accommodated by BFCF and BBCF Kits.

With a purging or pressurization unit, instrument grade tubing, a few tools and these kits in hand, a technician can complete the task of installation in a matter of one or two hours.Consider these kits as a time saver for your procurement team and a way to facilitate fast and easy installation of our products!

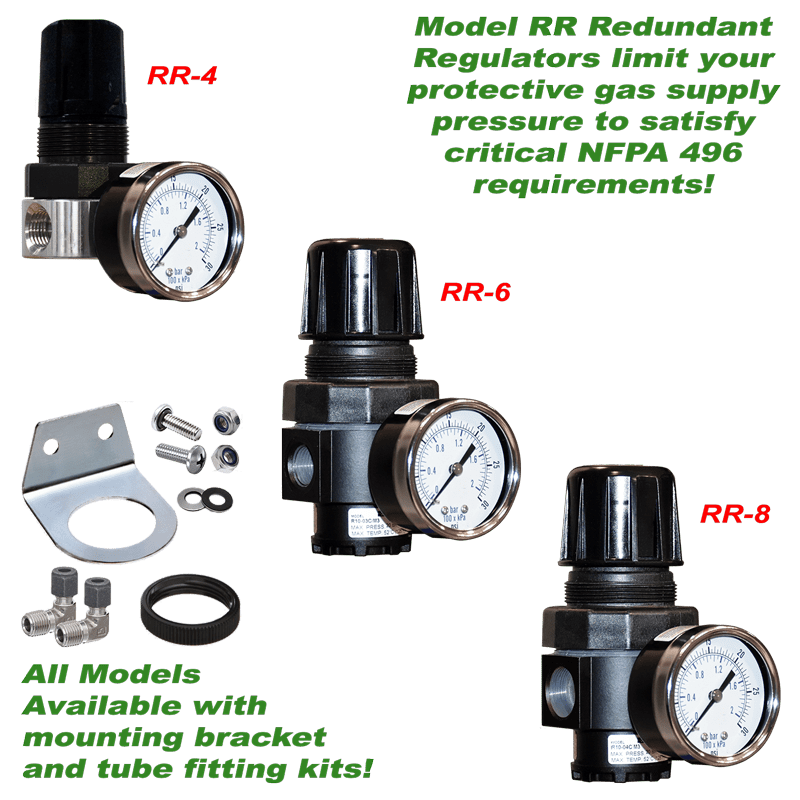

Best Purging Systems Corporation offers Model RR Redundant Regulators to satisfy NFPA 496 Section 4.3.1.1, which requires the pressure of the protective gas supply to be limited to ensure your protected enclosure is never subjected to the forces of excessive pressure.

These redundant regulators are sized to match our Type Y and Z Enclosure Pressurization Units, are furnished with a pressure gauge, can be rendered tamper-proof if desired, and are available with optional mounting brackets and tube fitting kits to simplify installation!

Best Purging Systems Corporation provides all necessary accessories to properly protect your enclosure!

Model RR Redundant Regulators are intended to satisfy NFPA 496 requirements for preventing the possibility of enclosure over-pressurization due to excessive protective gas supply pressure.Each regulator features a removable adjustment knob to render it tamper-proof at the user’s discretion.The regulators feature a 0-30 psi gauge, and when installed upstream of a Model 101A, 101B or 101C Enclosure Pressurization Unit, and properly calibrated as recommended on page 2, will serve as an up-stream protective gas supply safety device. Model RR Redundant Regulators are identical to the Enclosure Pressure Control Regulators of the Units they protect, so the adjustment knobs of both regulators are interchangeable if needed

Models RR-4, RR-6 & RR-8

Redundant Protective Gas supply Regulators

Intended for use as redundant, tamper-proof regulators for Pressurization Unit Models 101A, 101B & 101C when the Units are installed without Model PV Spark Arresting Purge Vents.

| Supply Pressure: | 120 PSI max |

| RR-4 Connections: | 1/4″ FPT - for Model 101A |

| RR-6 Connections: | 3/8″ FPT - for Model 101B |

| RR-8 Connections: | 1/2″ FPT - for Model 101C |

| Range: | 0-3 PSI |

| RR-4 Body: | Anodized Aluminum |

| RR-6 & RR-8 Bodies: | Painted Aluminum |

| Regulator Heads & Knobs: | Acetal Polymer Plastic |

| Regulator Seats: | Buna N Elastomer |

| Gauge: | Painted Steel Case, Plastic Lens w/ Chrome Ring & Brass Tube |

| Operating Temperature: | 40°F to 125°F |

| Optional Installation Kits | |

| Mounting Bracket: | 304 Stainless Steel |

| Bracket Fasteners: | 316 & 18/10 Stainless Steel w/ Neoprene Sealing Washers |

| Tube Fittings: | 316 Stainless Steel |

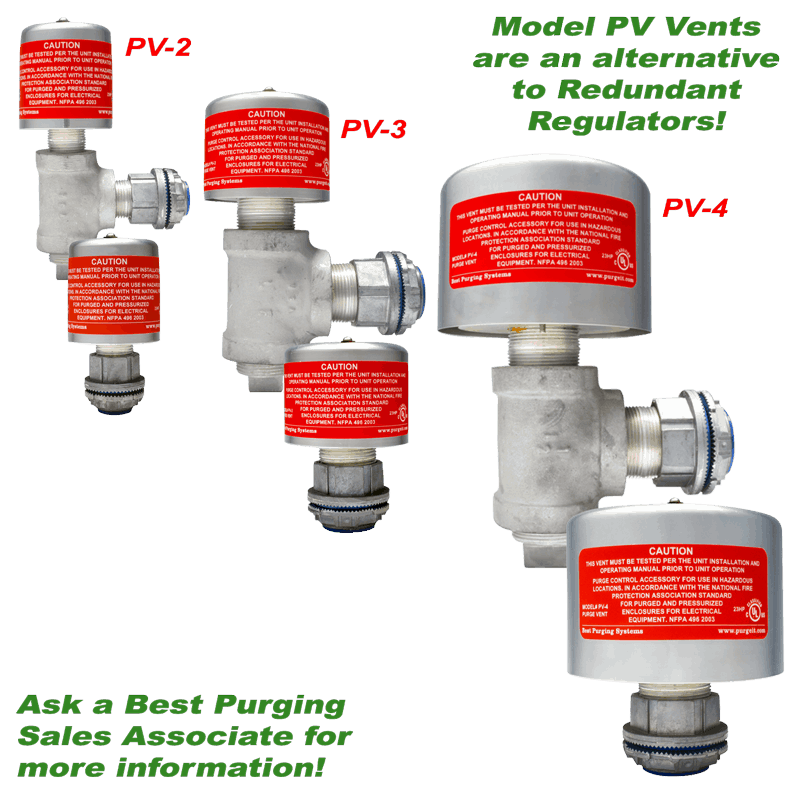

Best Purging Systems offers Spark Arresting Purge Vents to serve as an alternative to Model RR Redundant Regulators to satisfy NFPA 496 requirements to prevent excessive pressure from the protective gas supply from damaging your protected enclosure.

These vents mount easily to your protected enclosures, and provide additional protection when your pressurized enclosure contains a separate source of pressure, for protected enclosures containing analyzers, flow meters and other process equipment.

Best Purging Systems provides these accessories as an alternative to Redundant Regulators!

The Model PV Purge Vent is a gravity operated enclosure pressure relieving device designed to relieve excess pressure inside a protected enclosure, while preventing any sparks or burning material from escaping into a classified location.Model PV Purge Vents are designed for use exclusively with Best Purging Systems purge and pressurization products.Model PV is constructed of an aluminum cap, base and pipe fitting and features a stainless steel filter element and fasteners, to ensure maximum resistance against corrosive environments.

Model PV Purge Vents will begin to open when enclosure pressure exceeds approximately 0.8” w.c. and will fully open when enclosure pressure exceeds approximately 1.5”.All Model PV Purge Vents MUST be installed in a true vertical position for proper operation and are available in “T” (top mount) and “S” (side mount) configurations.The vents feature a conduit hub with sealing gasket to connect easily to a protected enclosure, or may be mounted remotely.

Model PV-2, PV-3 & PV-4

-T Top Mount & -S Side Mount Spark Arresting Enclosure Vents

Prevents over pressurization of the protected enclosure

| Common Specifications | |

| Materials: | Aluminum Cap & Fittings w/ Stainless Steel Filter Element & Fasteners. |

| Caution Nameplates: | Lexan |

| Operating Temperatures: | -20°F to 140°F |

| Model PV-2 - for Model 101A | |

| Mounting Hub Diameter: | 3/4″ |

| Nominal Flow Rate: | 4 scfm |

| PV-2-T Dimensions: | 4.5″ Tall x 2.5″ Diameter |

| PV-2-S Dimensions: | 6.5″ Tall x 5.25″ Overall |

| Model PV-3 - for Model 101B | |

| Mounting Hub Diameter: | 1 1/4″ |

| Nominal Flow Rate: | 12 scfm |

| PV-3-T Dimensions: | 4.5″ Tall x 3.5″ Diameter |

| PV-3-S Dimensions: | 8″ Tall x 5.5″ Overall |

| Model PV-4 - for Model 101C | |

| Mounting Hub Diameter: | 1 1/2″ |

| Nominal Flow Rate: | 30 scfm |

| PV-4-T Dimensions: | 6″ Tall x 5.5″ Diameter |

| PV-4-S Dimensions: | 10″ Tall x 7.75″ Overall |

Best Purging Systems Corporation provides these accessories to act as local alarms and alert operators and maintenance personnel to the loss of safe protected enclosure pressure.

These alarm devices can be mounted on or near the protected enclosure, are rated for the Hazardous Location and are perfect companions to our Enclosure Pressure Loss Alarm Switches.

Best Purging Systems Corporation provides all necessary alarm devices to complement our Units!

Models ERAB-2, RAB-2, RAB-1, RAH-2 & RAH-1

Remote Flashing Alarm Beacons & Audible Tone Horns

Provide visual and audible signals to summon Operators to fault conditions

| ERAB-2 | Economy Remote Alarm Beacon |

| Materials: | Aluminum Housing w/ Polyurethane Finish & Polycarbonate Outer Dome |

| Mounting: | Pendant w/ 3/4″ Conduit |

| Dimensions: | 7.5” H x 5.5” Diameter |

| Shipping Weight: | 2 Pounds |

| Operating Temperature: | -40° F to 104° F |

| Operating Voltage: | 12-24 VDC @ 1.70-0.70 Amps 24 VDC @ 0.70 Amps 120 VAC @ 0.21 Amps 240 VAC @ 0.13 Amps |

| Flash Rate: | 80 / Minute |

| Certification: | Class I, Div 2 – UL Listed, CSA Certified |

Area Classification Ratings for each device vary…

| RAB-1 | Div 1 Flashing Remote Alarm Beacon |

| Materials: | Cast Aluminum Body with Epoxy Finish & Glass Dome w/ Optional Guard |

| Mounting: | Pendant, Wall or Ceiling Mount w/ 3/4 Conduit Port |

| Dimensions: | 14.26″ – 15.48″ H x 8.80” Diameter |

| Shipping Weight: | 15.9 -19.8 Pounds |

| Operating Temperature: | -67° F to 150° F |

| Operating Voltage: | 24 VDC @ 1.9 Amps 120 VAC 50/60 Hz @ 1.14 Amps 240 VAC 50/60 Hz @ 1.14 Amps |

| Flash Rate: | 80 / Minute |

| Certification: | Class I, Div 1 – UL Listed, CSA Certified |

| RAB-2 | Div 2 Flashing Remote Alarm Beacon |

| Materials: | Cast Aluminum Body with Epoxy Finish & Glass Dome w/ Optional Guard |

| Mounting: | Pendant or Ceiling w/ 3/4″ Conduit Port |

| Dimensions: | 9.25” H x 5.5” Diameter |

| Shipping Weight: | 5 Pounds |

| Operating Temperature: | -31° F to 104° F |

| Operating Voltage: | 24 VDC @ 0.4 Amps 120-240 VAC @ 0.21-0.13 Amps 277 VAC @ 0.13 Amps |

| Flash Rate: | 60 / Minute or Steady Burn |

| Certification: | Class I, Div 2 – UL Listed, CSA Certified |

| RAH-1 | Div 1 Steady Tone Remote Alarm Horn |

| Materials: | Cast Aluminum Body |

| Mounting: | Pendant or Surface w/ 3/4″ Conduit Port |

| Dimensions: | 7.625” H x 6.875” D x 6.5” D |

| Shipping Weight: | 12 Pounds |

| Operating Temperature: | -13° F to 104° F |

| Maximum Sound: | 100 Decibels at 10 ft. (5 minute duty cycle) |

| Operating Voltage: | 24 VDC @ 1.2 Amps 120 VAC 50/60 Hz @ 0.20 Amps 240 VAC 50/60 Hz @ 0.10 Amps |

| Certification: | Class I, Div 1 – UL Listed, CSA Certified |

| RAH-2 | Div 2 Steady Tone Remote Alarm Horn |

| Materials: | Die Cast Zinc w/ Polyurethane Finish |

| Mounting: | Surface w/ 3/4″ Conduit |

| Dimensions: | 4.53” H x 6.02” W x 3.66” D |

| Shipping Weight: | 3 Pounds |

| Operating Temperature: | -65° F to 150° F |

| Maximum Sound: | 100 Decibels at 10 ft. |

| Operating Voltage: | 120VAC 50/60Hz @ 0.18 amps 240VAC 50/60Hz @ 0.09 amps |

| Certification: | Class I, Div 2 – UL Listed, CSA Certified |

Model RAH, RAB & ERAB Alarm Beacons and Horns are intended to provide local alarms for unit faults, high temperatures, loss of pressurization or ventilation and other situations that require immediate attention from local operators and maintenance staff members. They work in conjunction with any Unit featuring a pressure loss alarm switch, and may also serve as common alarms for other equipment.

Our Remote Alarm Beacons & Horns provide easily recognized visual and audible signals that summon operators and maintenance personnel to loss of safe pressure in your protected enclosures!

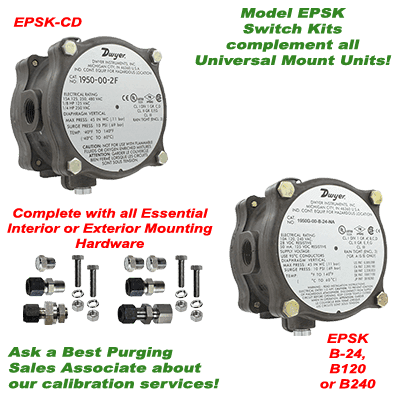

Best Purging Systems Corporation offers Model EPSK Explosion Proof Pressure Switch Kits to complement our Universal Mount Purge & Pressurization Units. These switches come complete with all essential fittings and mounting hardware, ready for installation and use.

When utilized in conjunction with Best Purging Systems Alarm Horns and Beacons, these switches can activate an alarm to warn operators and maintenance personnel to the loss of safe pressure in a protected enclosure.

Best Purging Systems Corporation provides all necessary accessories to complete your installation easily!

Model EPSK Explosion Proof Enclosure Pressure Switch Kits are accessories that provide a pressure loss alarm contact.They are intended to mount in a vertical stand-alone position to complement all universal mount Type Y and Z purging and pressurization systems, and are offered in a full range of area classification ratings to satisfy any Hazardous Location.

Models EPSK-CD, EPSK-B24, EPSK-B120 & EPSK-B240

Explosion Proof Pressure Switch Kits

Provides Form C Contact for audible or visual safe pressure loss alarms

| Common Specifications | |

| Set Point: | 0.15” w.c. ± 0.02” (on decrease) |

| Materials: | Die-Cast Aluminum Housing w/ Zinc Bolts |

| Dimensions: | 3.50″ H x 4.25″ Diameter |

| Mounting Style: | Diaphragm Vertical |

| Pressure Limits: | 45″ W.C. |

| Enclosure Rating: | NEMA 3, 7 & 9 (IP 54) |

| Switch Type: | Form C SPDT |

| Pressure Ports: | 1/8″ Female NPT |

| Conduit Port: | 1/2″ Female NPT |

Model EPSK-CD |

|

| Device Rating: | Class I, Division 1, Groups C & D |

| Contact Ratings: | 15 A @, 125, 250, 480 VAC, 60 Hz. Resistive 1/8 HP @ 125 VAC, 1/4 HP @ 250 VAC |

| Operating Temp: | -40°F to 140°F |

| Model EPSK-B24, EPSK-B120 & EPSK-B240 | |

| Device Rating: | Class I, Division 1, Groups B, C & D Class II, Division 1, Groups E, F & G |

| Contact Ratings: | 10 A, 120/240 VAC, 28 VDC Resistive 50 mA, 125 VDC |

| Operating Temp: | 0°F to 140°F |

| Operating Voltage: | 24 VDC ±10%. 120 or 240 VAC ±10% |

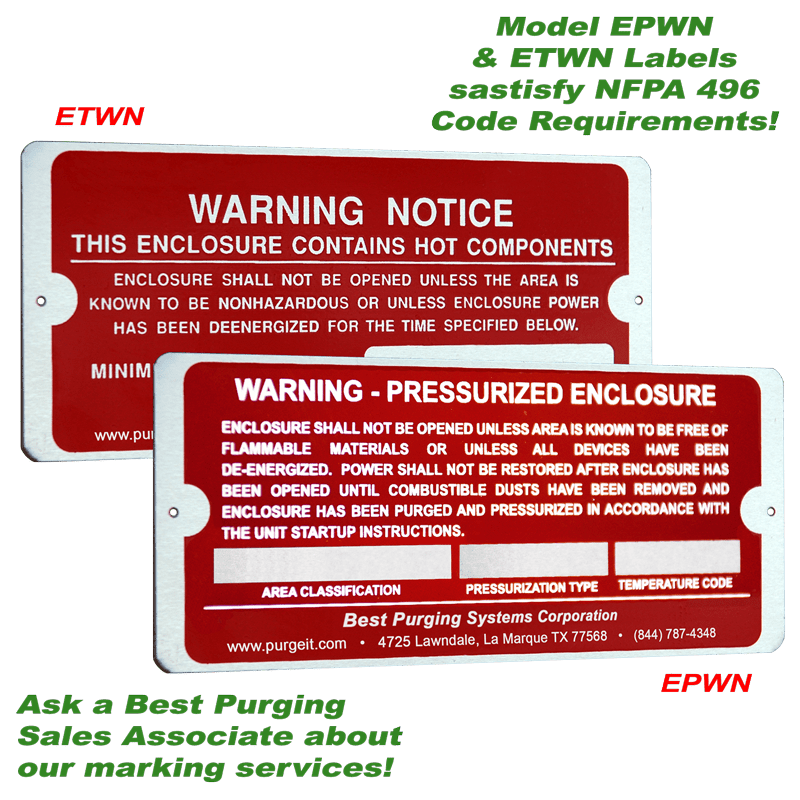

Best Purging Systems Corporation provides these nameplates to satisfy NFPA 496 Standard requirements. One Model EPWN is furnished with all Units, but NFPA 496 requires this label to be visible from all access points of a protected enclosure.

Model EPWN warns that the protected enclosure is pressurized, and provides other essential instructions for safe access. Model ETWN warns that the protected enclosure contains devices exceeding the surrounding atmosphere’s auto-ignition temperature.

Best Purging Systems Corporation provides all necessary labels to ensure total code compliance!

Model EPWN

Enclosure Pressurization Warning Nameplates

Provides code compliant labels for all pressurized enclosures, in accordance with NFPA 496 Code Requirements!

Model ETWN

Enclosure Temperature Warning Nameplates

Provides code compliant labels for pressurized enclosures containing hot components exceeding temperature codes, in accordance with NFPA 496 Code Requirements!

| Dimensions: | 5” W x 2” H |

| Mounting Hole Diameter: | 0.125″ |

| Adhesive Backing: | 3M® VHB® |

| Material: | Reverse Silkscreened Lexan® |

3M and VSB are registered trademarks of the 3M Corporation Lexan is a registered trademark of General Electric Corporation

IMPORTANT NOTES:

Door surfaces must be cleaned for maximum adhesion. One (1) Model EPWN Nameplate is supplied with all Best Purging System Units to meet minimum requirements, but NFPA 496 requires that this label be visible from all access points of a protected enclosure.

Best Purging System’s Model EPWN Enclosure Pressurization Warning Nameplate meets NFPA 496 Code requirements for all Type Y and Z Purging and Pressurization Unit applications.The nameplate warns that the protected enclosure may not be opened unless the area is safe or all unrated devices within the protected enclosure have been deenergized.To cover both Class II and Class I Areas, the warning also stipulates that all combustible dusts must be removed and the enclosure must be re-pressurized in accordance with all applicable purge or pressurization unit start-up instructions before power to the unrated devices is reenergized.

The Model ETWN Enclosure Temperature Warning Nameplate warns that the protected enclosure contains hot components, and that a specified cooling time must be observed before opening the protected enclosure door.Depending on your sites AHJ (authority having jurisdiction) these warnings may be circumvented by special permission of the operational management authority, in the event of a life-threatening emergency, or when the surrounding area is known to be free of flammable or combustible materials.Please contact a Best Purging Systems Sales Associate for more information regarding these essential accessories.

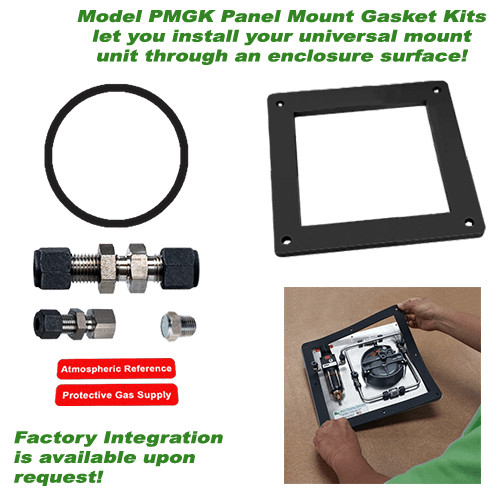

Best Purging Systems Corporation provides Model PMGK Panel Mount Gasket Kits to permit the installation of a universal mount pressurization unit through a cutout in the surface of a protected enclosure wall or door, and includes all essential gaskets, fittings and labels.

Utilize these kits to boost aesthetic and ergonomic values of protected enclosures, minimize the overall foot-print of protected enclosures in confined spaces and minimize exposed mechanical surface areas of protected enclosures in clean rooms.

Best Purging Systems Corporation provides these kits to enhance Universal Mount Units!

Model PMGK-101A, PMGK-101B & PMGK-101C

Panel Mount Gasket Kits

Provides all necessary gaskets, fittings and labels to facilitate panel mounting of Model 101A, 101B & 101C Universal Mount Pressurization Units!

| Unit Gasket: | Die-Cut Open Cell Neoprene w/ adhesive backing |

| Gauge Gasket: | Butyl Rubber |

| Union Fittings: | 316 Stainless Steel |

| Atmospheric Vent: | 316 Stainless Steel Body 304 Stainless Steel Element |

| Bulkhead Labels: | Velvet Lexan™ with VSB™ Adhesive |

IMPORTANT NOTES:

Unit Mounting Plate surfaces must be cleaned for maximum adhesion. Installation requires reversing the locations of a tubing connector fitting and a vent fitting on the back of the enclosure pressure gauge. Factory Integration is available.

– please contact a Sales Associate for more information.

Velvet Lexan™ and VSB™ are Trademarks of the 3M™ Company

Best Purging Systems Corporation offers Model PMGK Panel Mount Gasket Kits to enhance Model 101A, 101B and 101C Universal Mount Units. Model PMGK Kits feature a unit mounting plate gasket and an enclosure pressure gauge gasket to provide a positive seal.They also include two bulkhead unions, an atmospheric pressure reference vent fitting and essential bulkhead labels.

To utilize a Model PMGK on a universal mount pressurization unit, an installer must perform a simple modification to reverse the locations of a tubing connector fitting and a vent fitting on the back of the enclosure pressure gauge.The sealing gaskets must then be applied to the unit mounting plate and enclosure pressure gauge to form a seal resistant to rain and light wash down.However, Best Purging Systems can also integrate this kit upon request for a nominal fee, so the Unit you receive will be ready for immediate installation!For more information, please contact a Best Purging Systems Sales Associate or review our highly detailed Technical Bulletin.