TYPE Y & Z NFPA 496 ENCLOSURE PURGING UNITS

Did you know?

Our CEO developed the concept of “Rapid Exchange” in 1985, and our original enclosure vents featured a brass swing-check valve and a PVC pipe cap. Our vents are now more advanced, but many Units with those vents sporting brass valves and PVC caps are still in service today! Look around, and you might just find one!

Product Description

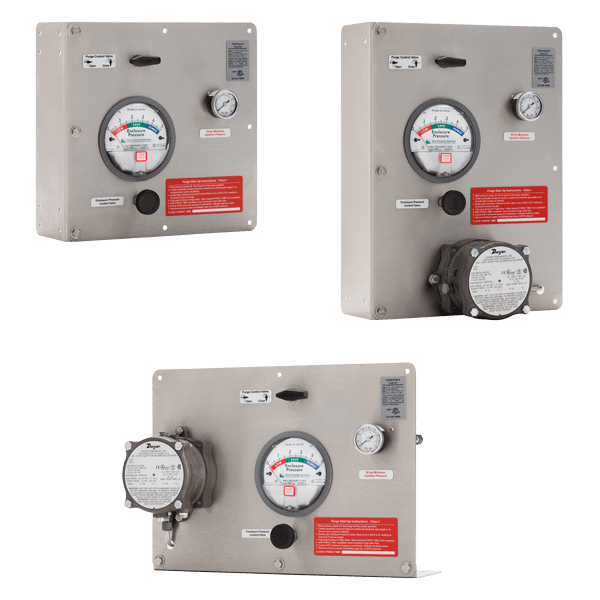

Best Purging Systems Type Y and Z Purge Units protect electrical equipment in Class I Hazardous Locations. When connected to a supply of protective gas these models will supply, regulate and monitor the protective gas supply to a protected enclosure; and are UL listed and designed to meet or exceed NEC – NFPA 70, NFPA 496, EN 50016 and IEC 60079-02 requirements.

Each Unit features a regulator that supplies a needle valve and ball valve in parallel to set enclosure pressure and purge enclosures quickly, when required during start-up. In addition, a color-coded analog differential pressure indicator is provided to displays enclosure pressure. Our Vertical and Horizontal Configuration Units also feature a Differential Pressure Switch available in several styles to provide a signal to indicate enclosure pressure loss.

When utilized for Type Z applications, these Units reduce the hazardous location rating inside the enclosure from Division 2/ Zone 2 to non-hazardous. This allows non-rated equipment to operate in Division 2/ Zone 2 areas.

When utilized for Type Y applications, these Units reduce the hazardous location rating inside the enclosure from Division 1/ Zone 1 to Division 2 / Zone 2. This allows Division 2/ Zone 2 equipment to operate in Division 1/ Zone 1 areas.

IMPORTANT NOTE: Model PV Spark Arresting Purge Vents installed on the protected enclosure are required for safe operation.

Please scroll down for product line reviews and technical bulletin links!

Product Line Details

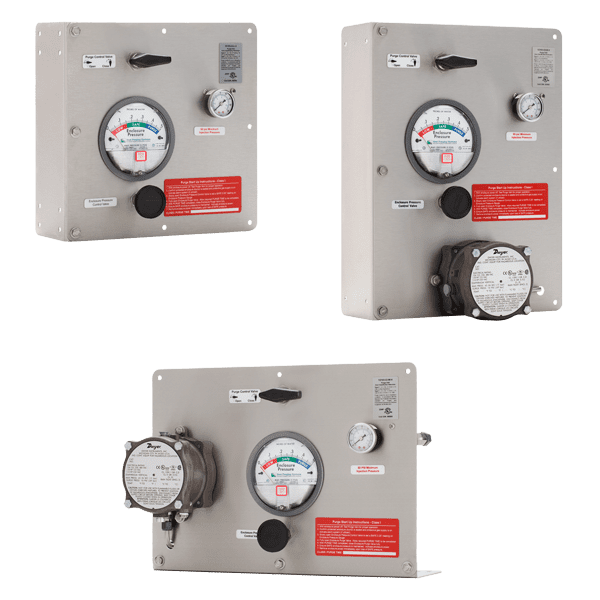

Model 102

Type Y & Z Purging & Pressurization Unit

Class I: 15 CF Maximum

CONFIGURATIONS

Universal Mount, less Pressure Switch

Mounts on any Side or Panel Mounts

Vertical Mount Unit, with Pressure Switch

Mounts on Left or Right Side

Horizontal Mount, with Pressure Switch

Mounts on Top or Bottom

Review our Technical Bulletin

High Resolution Technical Bulletin Low Resolution Technical BulletinPurchase a Unit Now!

Buy MODEL 102 UNIVERSAL UNIT NOW! Buy MODEL 102 VERTICAL UNIT NOW! Buy MODEL 102 HORIZONTAL UNIT NOW!

Model 103

Type Y & Z Pressurization Unit

Class I: 75 CF Maximum

CONFIGURATIONS

Universal Mount, less Pressure Switch

Mounts on any Side or Panel Mounts

Vertical Mount Unit, with Pressure Switch

Mounts on Left or Right Side

Horizontal Mount, with Pressure Switch

Mounts on Top or Bottom

Review our Technical Bulletin

High Resolution Technical Bulletin Low Resolution Technical BulletinPurchase a Unit Now!

Buy MODEL 103 UNIVERSAL UNIT NOW! Buy MODEL 103 VERTICAL UNIT NOW! Buy MODEL 103 HORIZONTAL UNIT NOW!

Model 104

Type Y & Z Pressurization Unit

Class I: 250 CF Maximum

CONFIGURATIONS

Universal Mount, less Pressure Switch

Mounts on any Side or Panel Mounts

Vertical Mount Unit, with Pressure Switch

Mounts on Left or Right Side

Horizontal Mount, with Pressure Switch

Mounts on Top or Bottom