Call (844) 787-4348

That's 844-PURGE-IT

UL LISTED TYPE Y & Z ENCLOSURE PRESSURIZATION UNITS

Product Operation

Best Purging Systems Type Y and Z Pressurization Units are easy to operate, with only one adjustment to set a safe pressure on your protected enclosure, but the sequence and performance of critical procedures is essential to ensure your protected enclosure is protected in complete accordance with NFPA 496 requirements.

Regardless of which model you select, it is most essential to ensure power to ordinary location devices within a protected enclosure never remain energized for any significant length of time if the protected enclosure is not pressurized.

Prior to initiating start-up, these conditions must be established: First, ensure that the protective gas supply is on and that the alarm system (if utilized) is activated. In addition, it is also essential to ensure the protective gas redundant regulator is set to at least five (5) psi (if utilized) or that protection vent (if utilized) is pre-tested to ensure proper operation, in accordance with instructions on the vent label.

START-UP PROCEEDURES FOR CLASS II AREAS

For Model 101A, 101B and 101C applications in Class II Areas, start-up requires three procedures. First, it is essential to remove all dust from the protected enclosure by whatever means is the most efficient and effective. Next, the protected enclosure should be closed and fully sealed. As the third procedure, adjust the enclosure pressure control regulator slowly to establish a “Safe” reading on the enclosure pressure gauge.

After safe conditions are established, it is essential to confirm the protected enclosure’s “Safe” pressure is stable before energizing power to the ordinary location electrical equipment within the protected enclosure. Loss of “Safe” pressure requires immediate attention. De-energize power if “Safe” pressure cannot be restored within a reasonable amount of time.

START-UP PROCEEDURES FOR CLASS I AREAS

For Model 101A applications in Class I Areas, start-up is initiated by closing and sealing protected enclosure. The enclosure pressure control valve must then be opened slowly to establish a “Safe” reading on the enclosure pressure gauge.

If the surrounding atmosphere contains more than trace amounts of flammable gases or vapors or if testing of the atmosphere is not performed, the ordinary location devices within the protected enclosure should not be energized until the protected enclosure atmosphere is rendered safe by sustained pressurization in accordance with the Unit Start-Up Instructions.

After safe conditions are established, it is essential to confirm the protected enclosure’s “Safe” pressure is stable before energizing power to the ordinary location electrical equipment within the protected enclosure. Loss of “Safe” pressure requires immediate attention. De-energize power if “Safe” pressure cannot be restored within a reasonable amount of time.

For more information, please review our Installation and Operation Manuals below.

Operation is easy, but essential steps must be performed to ensure safe operation!

As noted above, procedures for Model 101A Class I applications and Model 101A, 101B and 101C Class II applications are different, but equally important to ensure the safety of your facility and colleagues.

In Class I Areas, it is essential to test the surrounding atmosphere. If this procedure is not performed, or if the area contains more than trace amounts of flammable gases or vapors, it is essential to allow sufficient time for the Model 101A Unit to purge the enclosure before energizing power to the ordinary location devices located within the protected enclosure.

In Class II Areas it is essential to first remove all traces of combustible dusts that may have accumulated within the protected enclosure prior to energizing power to the ordinary location devices located within the protected enclosure. Dust removal should be performed carefully, with emphasis concentrated around any electrical devices that feature exposed electrical relay or contactor contacts, switches and any other devices capable of creating an ark or spark during normal operation.

Pressurization Unit Installation, Operation & Maintenance Manuals

All links below will open in a separate window for your convenience.

Click any Icon to open an On-Line Booklet with Sharing and Download Options

Click the High or Low Resolution Download Buttons to open Conventional PDF Documents

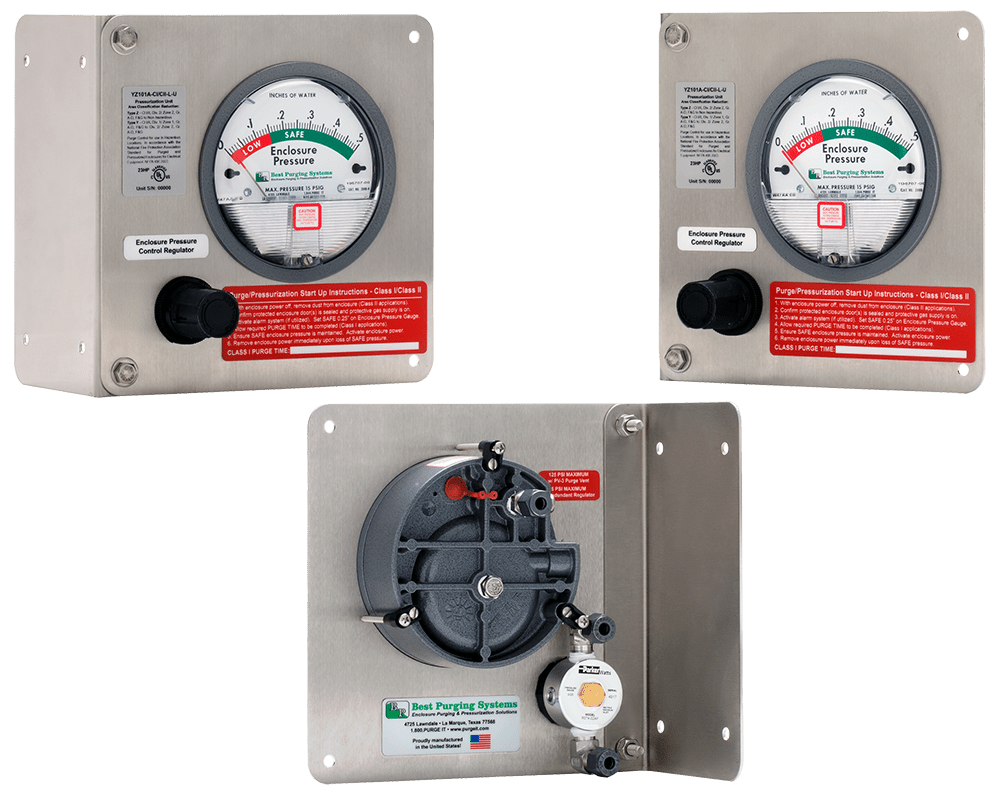

Model 101A

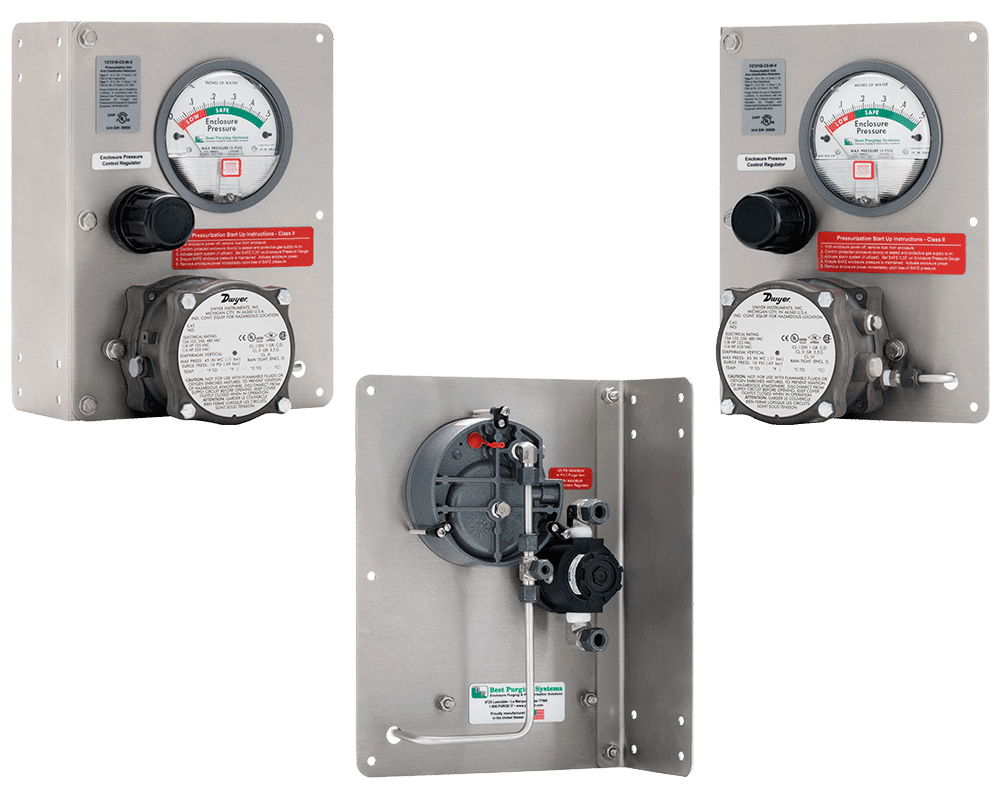

Model 101B

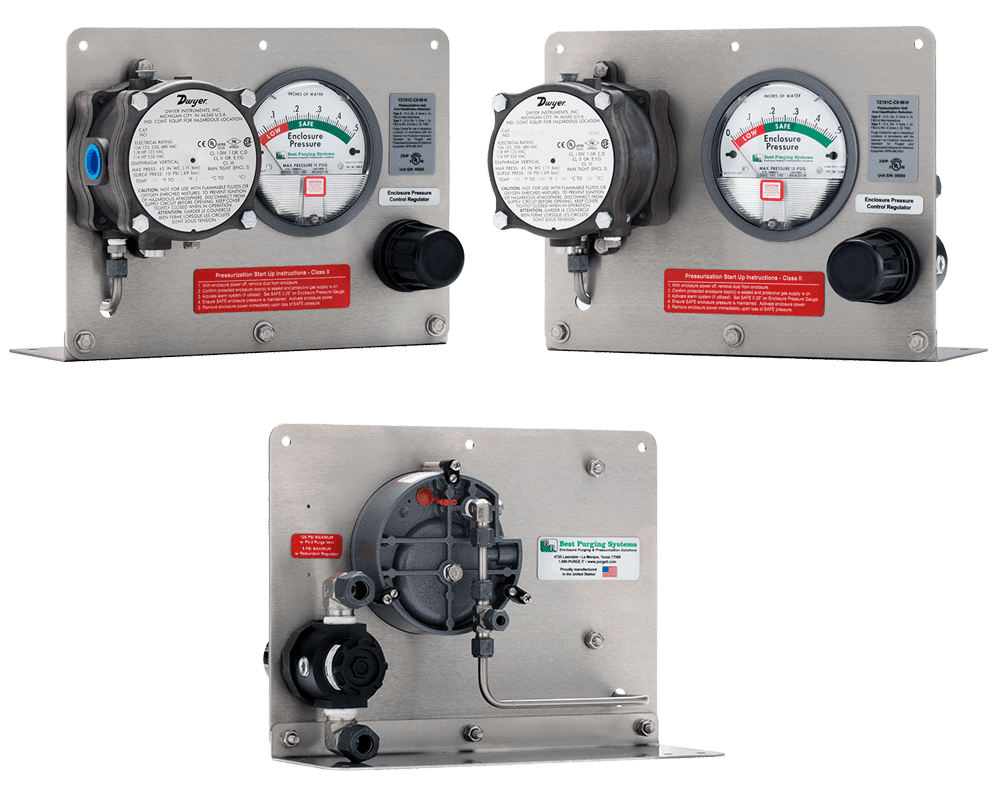

Model 101C