Call (844) 787-4348

That's 844-PURGE-IT

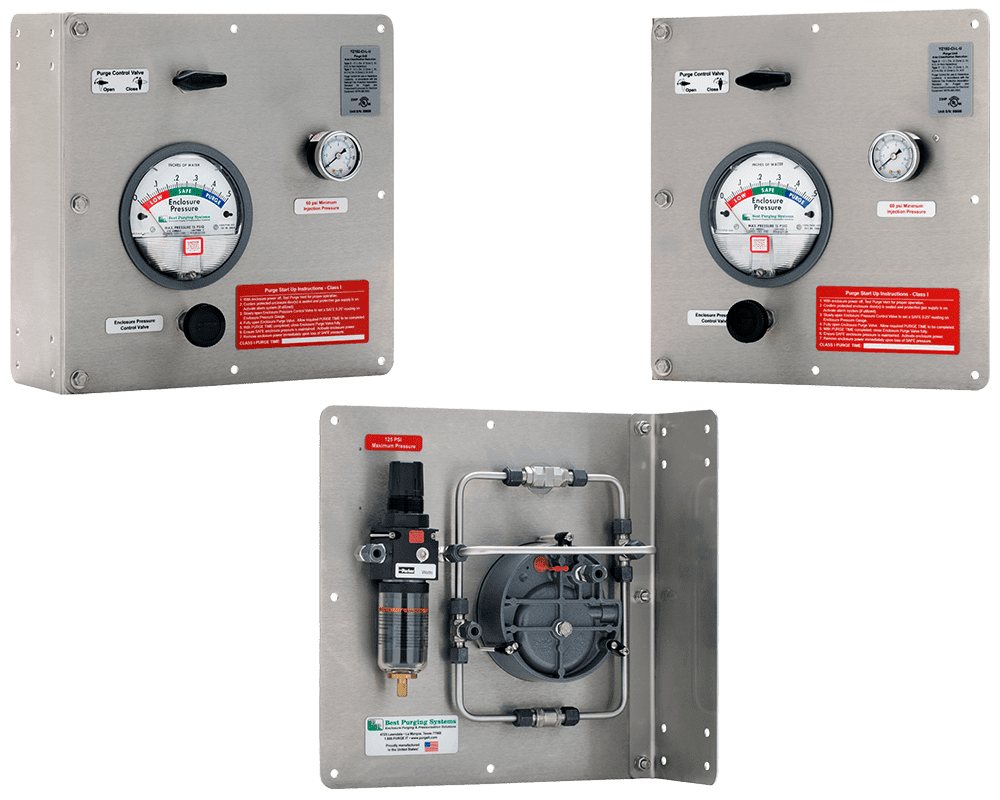

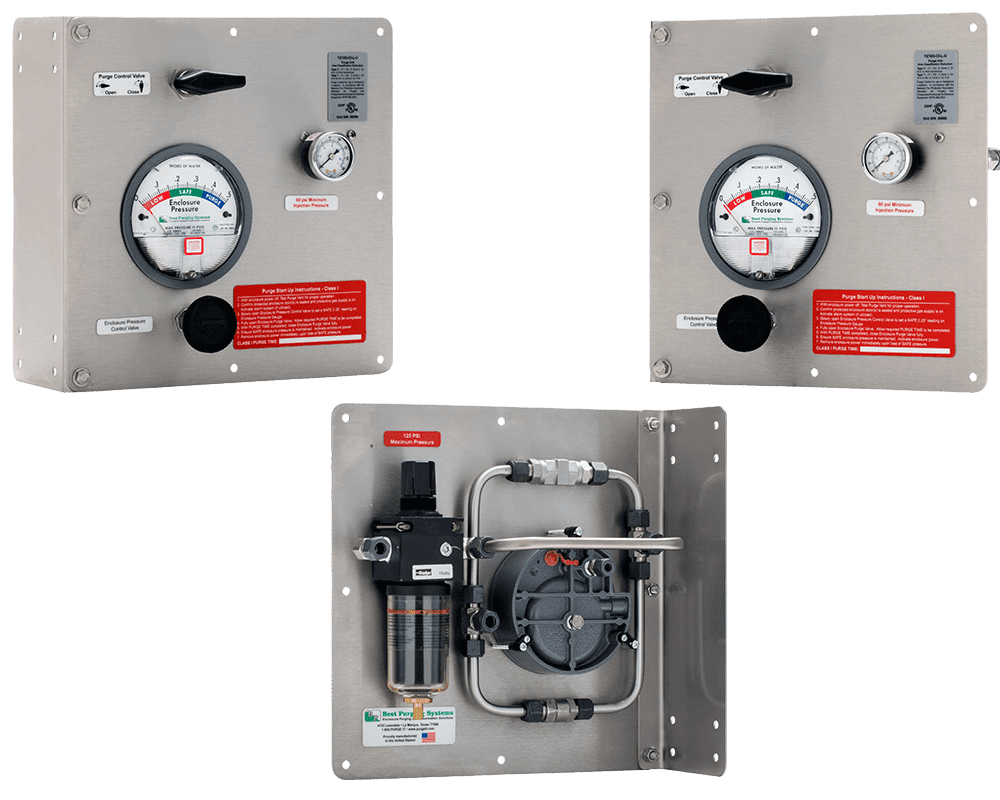

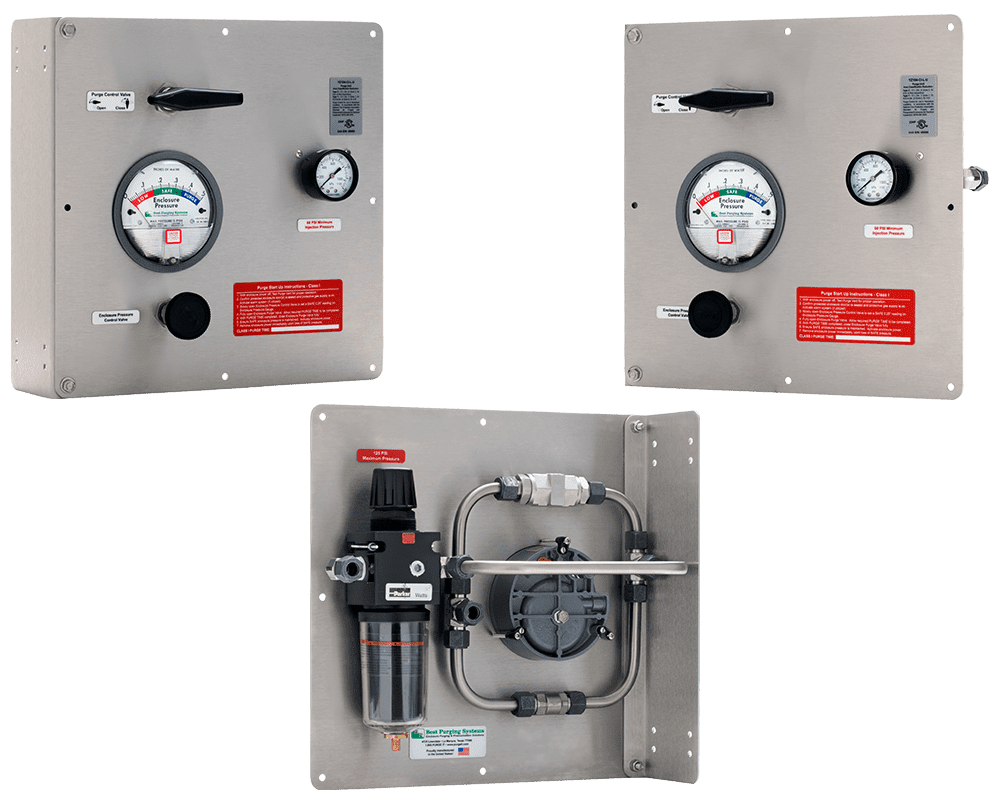

UL LISTED TYPE Y & Z ENCLOSURE PURGING UNITS

For more information, please review our Installation and Operation Manuals below.

Product Operation

Best Purging Systems Type Y and Z Purging Units are easy to operate, with only one adjustment to set a safe pressure on your protected enclosure, followed by a fast purging process to remove any potential concentrations of flammable gases or vapors from the protected enclosure. However, the sequence and performance of critical procedures is essential to ensure your protected enclosure is protected in complete accordance with NFPA 496 requirements.

Regardless of which model you select, it is most essential to ensure power to ordinary location devices within a protected enclosure never remain energized for any significant length of time if the protected enclosure is not pressurized.

Prior to initiating start-up, these conditions must be established: First, ensure that the protective gas supply is on, that the Unit’s regulator is set to the minimum injection pressure set point, and that the alarm system (if utilized) is activated. In addition, it is also essential to pre-test the required purge vent to ensure proper operation, in accordance with instructions on the vent label.

Start-up is initiated by closing and sealing the protected enclosure. Next, the enclosure pressure control valve must be opened slowly to set a “Safe” 0.25″ reading on the enclosure pressure indicator. The unit’s purge control valve must then be engaged to purge the enclosure of any potential concentrations of flammable gases or vapors, unless the surrounding area and enclosure compartment are tested prior to start-up and known to contain no more than trace amounts of flammable gases or vapors.

Operation is easy, but essential steps must be performed!

If testing is not performed to verify that the surrounding atmosphere contains no more than trace amounts of flammable gases or vapors, the purge control valve must be engaged to purge the protected enclosure for the required time marked on unit’s start up instructions nameplate or for 5 minutes, minimum.

Afterwards, it is essential to confirm the protected enclosure’s “Safe” pressure is stable before energizing power to the ordinary location electrical equipment within the protected enclosure. Loss of “Safe” pressure requires immediate attention. De-energize power if “Safe” pressure cannot be restored within a reasonable amount of time.

Purge Unit Installation, Operation & Maintenance Manuals

All links below will open in a separate window for your convenience.

Click any Icon to open an On-Line Booklet with Sharing and Download Options

Click the High or Low Resolution Download Buttons to open Conventional PDF Documents