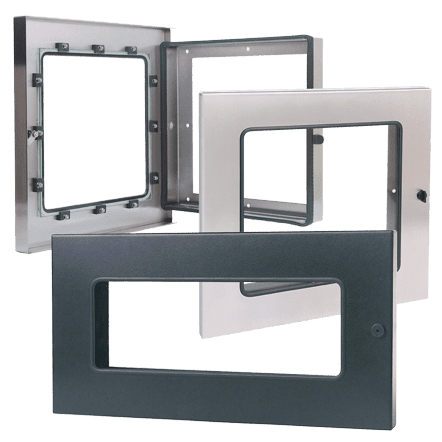

PURGED & PRESSURIZED DEVICE COVERS

Model Number Matrix

The Model Number Segments below specify standard features and options for our Purgeable Instrument Access Doors.

More Information is provided below each Segment, to guide you through the review process.

Please review our Model Number Selection Notes as indicated by red asterisk and note numbers following some segments

Please also review our Additional Information Requirements to ensure you understand all product selection parameters.

If you require assistance, please know a helpful Best Purging Systems Sales Associate is standing by to assist you!

Typical Model Number:

Model Number | PIAD | – | AA | – | 12 | – | 2 | – | CG | – | 1 | – | AH |

Segments | 1 | 2A & 2B | 3 | 4 | 5A & 5B | 6 | 7A & 7B |

Model Number | PIAD | – | AA | – |

| Segments | 1 | 2 |

12 | – | 2 | – | CG |

|---|---|---|---|---|

| 3 | 4 | 5 |

| – | 1 | – | AH |

|---|---|---|---|

| 6 | 7 |

Segment 1 – Model Designator

| PIAD | Purgeable Instrument Access Door |

Best Purging Systems offers Purgeable Instrument Access Doors in custom sizes with a wide variety of material, finish and hardware items. As an added benefit, their unique design permits easy replacement of windows, gasket and latches, so your PIAD can provide years of service!

Segment 2 – Window Size Range *1

| Segment 2A: Hinge Side Span | Segment 2B: Adjacent Side Span | ||

| A | 4" - 12" | A | 4" - 12" |

| B | 12" - 24" | B | 12" - 24" |

| C | 24" - 36" | C | 24" - 36" |

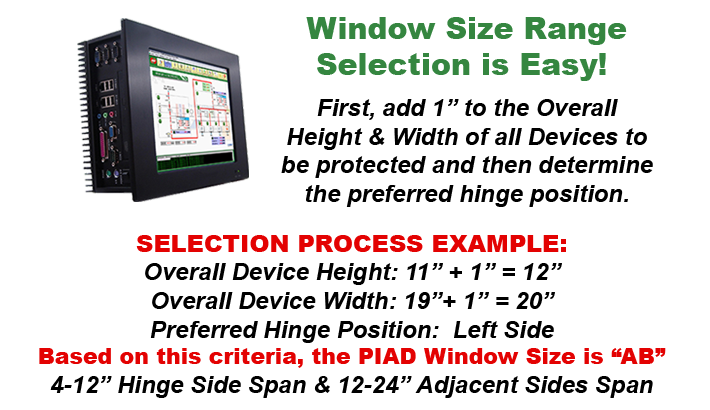

Selecting a window size first requires that you measure all devices as they will be positioned in your panel to determine their overall height and width. You should then add 1″ to both dimensions to ensure easy visibility of your devices. You then need only determine where you prefer to position your hinge, so the door swings open in a manner which provides the best access to your devices.

Our door hinges open on a “0” radius, so no additional clearance is required on the hinge side, but we recommend that you also provide 5″ of free and clear space on all sides of your overall device dimensions to ensure adequate clearance between other panel mounted devices and your PIAD door.

Segment 3 – NEMA Rating *2

| 12 | NEMA 12 |

| 04 | NEMA 04 |

| 4X | NEMA 4X |

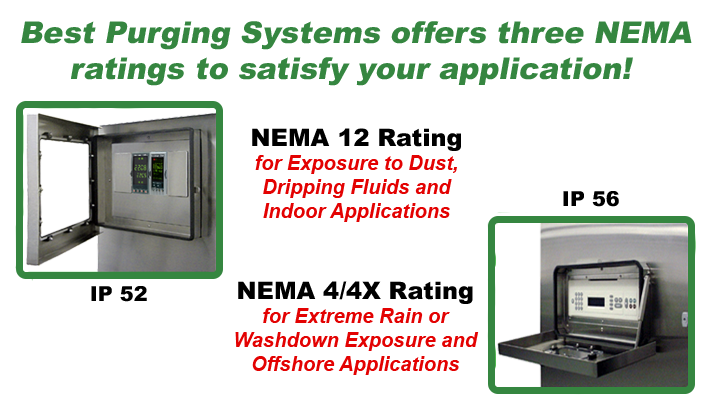

Best Purging System Purgeable Instrument Access Doors are designed to meet or exceed NEMA 12, 4 or 4X Ratings and equivalent IP Ratings, for indoor or outdoor applications and potential exposure to rain, washdown and corrosive atmospheres or chemicals.

Our NEMA 12 Rated PIADs feature mounting frames with squared corners. This is an efficient design that’s easily manufactured, but not suitable for outdoor applications or exposure to rain or washdown.

Our NEMA 4/4X Rated PIADs feature mounting frames with 45 degree corners, to maximize our replaceable door gasket sealing capabilities. This advanced design achieves a total seal that has been thoroughly tested to resist direct washdown and deluge rain conditions.

Please visit our Optional Features Page for more information or contact a Best Purging Systems Sales Associate for assistance with selection of a proper NEMA Rating,

Segment 4 – PIAD Depth *3

(internal clearance)

| 2 | 2” Depth (Standard) |

| 3 | 3" Depth |

| 4 | 3" Depth |

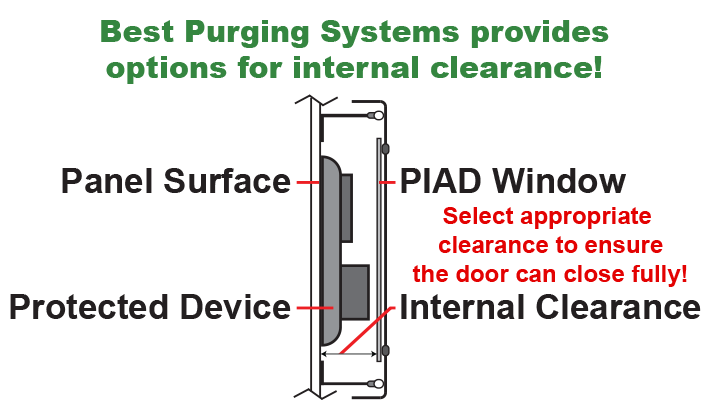

Selection of PIAD Depth determines the internal clearance from the rear side of the window to the panel surface. Best Purging Systems offers a 2″ Depth as standard which accommodates most panel mounted equipment easily. However, when required, we also offer 3″ and 4″ Depths.

If your circumstances require more than 4″ of clearnace, please contact a Best Purging Systems Sales Associate.

Segment 5 – Mounting Frame, Door & Window Material

| Segment 5A: Frame & Door Material | |

| C | 14 Gauge Carbon Steel *4 |

| S | 14 Gauge 304 Grade Stainless Steel |

| X | 14 Gauge 316 Grade Stainless Steel |

| C | Custom Material *6 |

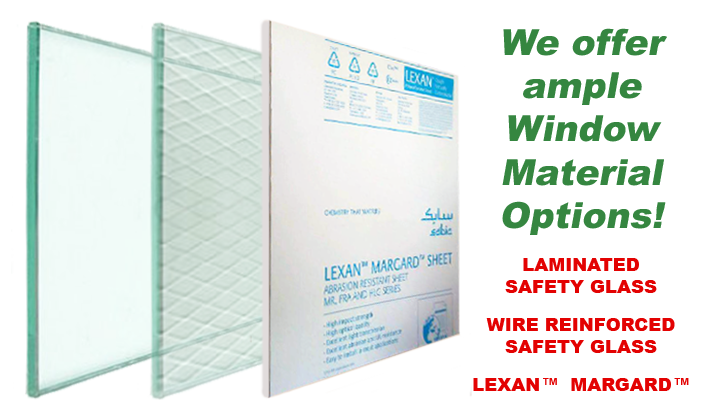

| Segment 5B: Window Material | |

| G | 1/4″ Laminated Safety Glass *5 |

| L | 1/4″ Lexan™ Margard™ MR-10 |

| W | 1/4″ Wire Reinforced Safety Glass *5 |

| N | No Window |

| U | Custom Material *6 |

As one of the most significant advantages of purchasing a Purgeable Instrument Access Door from Best Purging Systems Corporation, we offer a wide variety of materials to best match the material and finish of your protected enclosure! Consider the material of your protected enclosure when making this Segment selection, and note the only limitation is selection of carbon steel material in combination with a NEMA 4X rating in Segment 3. By requesting matching materials, you ensure that the corrosion resistance integrity of the protected enclosure is equalled in all respects by the Purgeable Instrument Access Door.

When choosing your window material please consider the following factors in relation to the requirements for your particular application: Lexan™ Margard™ MR-10 has the highest degree of impact resistance, at a ratio of nearly 10:1 when compared to laminated or wire reinforced safety glass across a broad spectrum of various conditions. Laminated safety glass has the maximum degree of transparency and resistance to UV rays, and along with wire reinforced safety glass is extremely scratch resistant.

However, Laminated and Wire Reinforced Safety Glass are not available in our two largest Window Size Ranges, due to a tendency to crack when flexed or twisted along the axis of any unhinged side. Temperature resistance of all three materials is similar, but Lexan™ Margard™ MR-10 is far less likely to crack upon impact at extreme temperatures, and does not shatter upon impact like laminated or wire reinforced safety glass. For more information about each window material and assistance in selecting the right material for your application, please contact a Sales Associate.

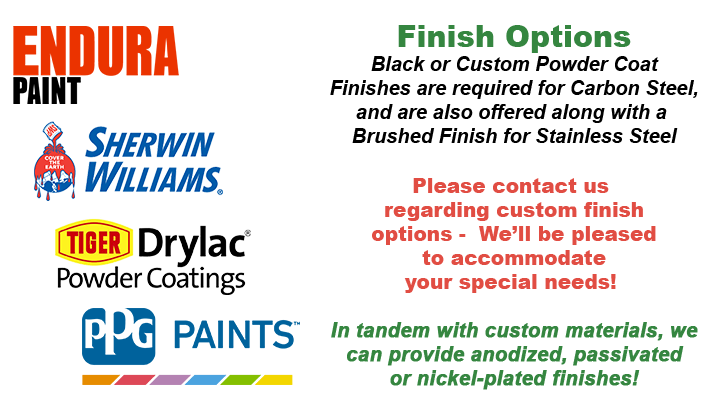

Segment 6 – Mounting Frame & Door Finish

| 1 | Black Powder Coat |

| 2 | Custom Color Powder Coat |

| 3 | Brush Finish Parallel to Hinge Side (Stainless Steel only) |

| 4 | Brush Finish Perpendicular to Hinge Side (Stainless Steel only) |

| U | Custom Finish *6 |

As yet another significant advantage of purchasing a Purgeable Instrument Access Door from Best Purging Systems Corporation, we offer a variety of finishes to complement your protected enclosure! But when details matter, we can offer virtually any finish you desire, including custom powder coat colors, along with anodized, passivated or nickel-plated finishes! Simply select Custom Finish for this segment of your PIAD Model Number, and supply your special requirements to us in writing to get the process started.

Segment 7 – Latch Type & Operator Style

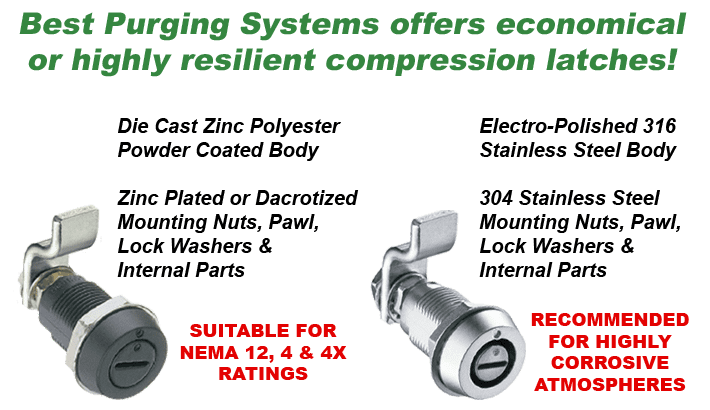

| Segment 7A: Latch Type (material & finish) | |

| A | Black Polyester Powder Coated Die Cast Zinc *7 |

| S | Electro-Polished 316 Grade Stainless Steel |

Best Purging Systems provides hand, tool or key operated vice-action compression latches with two material options to meet your particular needs for durability and corrosion resistance. The black powder coated die cast zinc latch is best suited for our powder coated carbon steel frame and door material option. It is our most popular latch, economical and salt spray tested, but may not survive extremely corrosive environments. The electro-polished 316 stainless steel latches are best suited for 304 or 316 grade stainless steel mounting frame and door material options, and offer the highest level of durability against extremely corrosive environments. However, you are encouraged to select the latch material of your choice, and due to their outstanding durability, no limitations are applied to their selection.

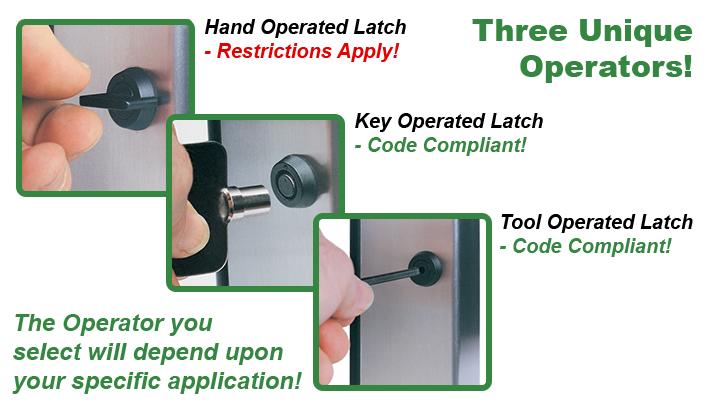

| Segment 7B: Operator Style | |

| H | Hand Operated Compression Latch |

| K | Key Operated Compression Latch *8 |

| T | Tool Operated Compression Latch *9 |

Best Purging Systems provides hand, tool or key operated vice-action compression latches to secure your Purgeable Instrument Access Door, which are all acceptable for Type Y & Z purging and pressurization applications. In regard to the use of Hand Operated Latches for Type X applications, it is important to determine if an exception to NFPA 496 Section 5.5.2 is permissible by your Safety Management Team or Authority Having Jurisdiction or critical to proper operation of the devices protected by the Purgeable Instrument Access Door. Otherwise, in accordance with this NFPA 496 requirement, all devices within the protected enclosure that are not suitable for the Hazardous (classified) Area in the absence of Type X pressurization must be de-energized prior to opening the Purgeable Instrument Access Door. However, if you select Key or Tool Operated Latches, they are totally compliant with this important NFPA 496 requirement!

* MODEL NUMBER SELECTION NOTES:

- Selection of PIAD Size Range is based on two letters. The first letter determines the span of the hinged side of your PIAD. The second letter determines the span of the adjacent sides. Please note this selection has no bearing on your actual hinge location.

- Corresponding with selection of NEMA 4X, we recommend selection of Electro-Polished 316 Grade Stainless Steel Latch Material in Segment 7 for highly corrosive atmospheres.

- Selection of PIAD Depth determines the internal clearance from the rear side of the window to the panel surface. 2″ Depth is standard, and 3″ and 4″ Depths are available at a slightly increased cost.

- Carbon Steel Material may not be selected in combination with a NEMA 4X Rating in Segment 3.

- Wire Reinforced Safety Glass should only be selected when impact hazards are immanent, due to viewing obstructions created by wire.

- Please provide custom mounting frame and door material, window material and mounting frame and door finish specifications in writing at time of order.

- Die Cast Zinc Compression Latch Material is suitable for NEMA 12, 4 and 4X Ratings, but Stainless Steel Latch Material is recommended for highly corrosive atmospheres.

- Key Operated Compression Latch Operators require a special key to operate. One (1) key is supplied with each unit, but extra keys are available on request.

- Tool Operated Compression Latch Operator requires a 5/32″ hex (allen) head tool to operate (not supplied)

ADDITIONAL INFORMATION REQUIREMENTS:

- To request a quote or place an order, we will require four additional bits of information, as follows, that may be supplied as notes accompanying any RFQ or PO.

- The actual Window Height you require in inches. Please note we accept increments as small as 0.125″ (1/8″), but the size must be within a range of 4 to 36 inches maximum, unless you require a custom size PIAD.

- The actual Window Width you require in inches. Like the height dimension, please note we accept increments as small as 0.125″ (1/8″), but the size must be within a range of 4 to 36 inches maximum, unless you require a custom size PIAD.

- The hinge location, specified as either the left or right side or the top or bottom.

- As an option, if you selected a 304 or 316 Stainless Steel Material with a grain direction that will be parallel or perpendicular to the hinge, please specify the direction of the grain (as either horizontal or vertical) that you require to match the direction of your enclosure grain, if applicable.

- We also encourage you to send us any drawings or documents that may assist us to ensure your PIAD will fit properly and meet your needs.

Please note that items 3 & 4 above are requested to ensure we build your PIAD in exact accordance with your requirements and to verify the PIAD Size Range and PIAD Finish you selected above.

You may rest assured we’ll send you a drawing for approval before we get started or contact you if we suspect any potential issues.