Call (844) 787-4348

That's 844-PURGE-IT

ENCLOSURE PRESSURIZATION SYSTEMS

Specifications

We take great effort and care to provide you with all essential Pressurization Unit specifications, and we’ll be pleased to provide any additional information you may require upon request.

Simply click any item below for the data you require, and feel free to call us if you have any questions. Please also note all data below is provided in our Technical Bulletins for your convenience.

Click any item for more information…

The following chart provides all unit dimensions and weights based on the unit size along with factors that affect these specifications.

Please use this chart to ensure our products will fit within the available space on your protected enclosure!

Flange Mounted Model YZ101A Pressurization Units

| Model Number | Unit Height | Unit Width | Overall Unit Depth | Unit Weight |

| YZ101A-CI/CII-L-U | 8″ | 8″ | 5.875″ | 3.5 lbs. |

| YZ101A-CI/CII-W-V or B-V | 12″ | 9″ | 7.625″ | 8.0 lbs. |

| YZ101A-CI/CII-W-H or B-H | 9″ | 12″ | 7.625″ | 8.0 lbs. |

Flange Mounted Model YZ101B Pressurization Units

| Model Number | Unit Height | Unit Width | Overall Unit Depth | Unit Weight |

| YZ101B-CII-L-U | 9″ | 9″ | 6.375″ | 5.0 lbs. |

| YZ101B-CII-W-V or B-V | 12″ | 9″ | 7.625″ | 9.0 lbs. |

| YZ101B-CII-W-H or B-H | 9″ | 12″ | 7.625″ | 9.0 lbs. |

Flange Mounted Model YZ101C Pressurization Units

| Model Number | Unit Height | Unit Width | Overall Unit Depth | Unit Weight |

| YZ101C-CII-L-U | 9″ | 9″ | 6.375″ | 5.5 lbs |

| YZ101C-CII-W-V or B-V | 12″ | 9″ | 7.625″ | 10.5 lbs. |

| YZ101C-CII-W-H or B-H | 9″ | 12″ | 7.625″ | 10.0 lbs. |

Universal Unit Interior & Exterior

Panel Mounting Depths

| Model Number | Interior Depth | Exterior Depth |

| YZ101A-CI/CII-L-U | 2.5″ | 1.75″ |

| YZ101B-CII-L-U | 2.5″ | 2.25″ |

| YZ101C-CII-L-U | 3.25″ | 2.25″ |

All information above is subject to change without notice and is provided for reference only.

Overall Unit & Interior Depths exclude clearances required for tubing connections.

Consult a Best Purging Systems Corporation Sales Associate for specific unit information

at time of inquiry or order.

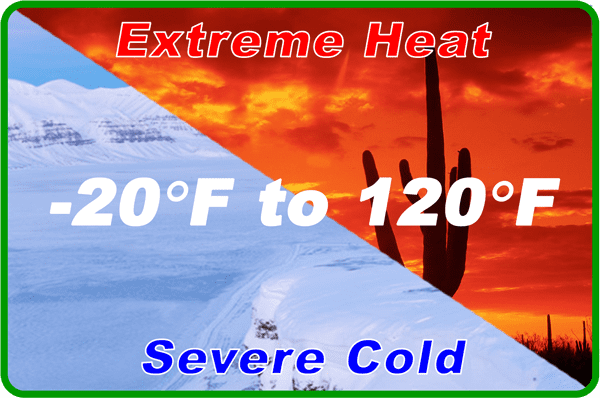

The following chart provides an overview of minimum and maximum operating temperature to ensure our unit is compatible with your specific application.

Please contact a Best Purging Systems Corporation Sales Associate for applications exceeding the ranges stated below.

Model Number | Minimum Temperature | Maximum Temperature |

All Units | -20°F | 120°F |

Operating units within the posted temperature ranges will insure optimum unit performance. Contact a Best Purging Systems Corporation Sales Associate for more information at time of inquiry or order.

The following chart provides all critical

specifications regarding capacities, protective gas supply requirements, connection sizes

and performance factors.

Please use this chart to ensure your installation

team is properly prepared and you have a

sufficient protective gas supply!

| Model 101A | Model 101B | Model 101C | |

| Class I Applications | Up to 2 cubic feet | Not Applicable | Not Applicable |

| Class II Applications | Up to 10 Cubic Feet | Up to 50 Cubic Feet | Up to 250 Cubic Feet |

| Protective Gas Supply * | Air or Inert Gas | Air or Inert Gas | Air or Inert Gas |

| Unit Supply Pressure w/ Purge Vent | 80 – 125 psi max | 80 – 125 psi max | 80 – 125 psi max |

| Unit Supply Pressure w/ Redundant Regulators | 5 psi max | 5 psi max | 5 psi max |

| Unit Supply Connection | 1/4″ tube fitting | 3/8″ tube fitting | 1/2″ tube fitting |

| Enclosure Supply Connection | 1/4″ tube fitting | 3/8″ tube fitting | 1/2″ tube fitting |

| Enclosure Reference Connection | 1/4″ tube fitting | 1/4″ tube fitting | 1/4″ tube fitting |

| Safe Enclosure Pressure | 0.25″ w.c. | 0.25″ w.c. | 0.25″ w.c. |

| Safe Pressure Flow Rate ** | 0.1 – 3.5 SCFH per cf | 0.1 – 3.5 SCFH per cf | 0.1 – 3.5 SCFH per cf |

| Class I Area Purge Time *** | 5 Minutes Minimum | Not Applicable | Not Applicable |

| Switch Set Point on Decrease | 0.15” w.c. ± 0.02” | 0.15” w.c. ± 0.02” | 0.15” w.c. ± 0.02” |

*Air must contain no more than trace

amounts of flammable vapors.

** Enclosure integrity determines

safe pressure flow rate.

*** Purge Time dependent on air flow rate at Safe Pressure – contact a Sales

Associate for more information.

Reliable, industrial-grade materials and components guarantee optimal unit performance in the harshest industrial environments!

Please use this chart to ensure our product’s compatibility with your specific application!

| Unit Components | |

| Valve & Fitting Bodies, Ferrules & Unit Fasteners: | 316 Stainless Steel |

| Tube Fitting Compression Nut Coating: | Molybdenum Disulfide |

| Enclosure Pressure Gauge Lens: | Acrylic w/ Neoprene O-Ring |

| Enclosure Pressure Gauge Body: | Cast Aluminum w/ Epoxy Finish |

| Atmospheric Reference: | 316 Stainless Steel Body & 304 SS Element |

| Indelible Unit Nameplates: | 0.10″ Velvet Lexan™ w/ VSB™ Adhesive |

| Pressure Control Regulator Head & Knob: | Acetal Polymer Plastic |

| Pressure Control Regulator Body: | Zinc w Buna N Elastomers |

| Pressure Switch Body: | Cast Aluminum w/ Epoxy Finish |

| Pressure Switch Bolts & Contacts: | Zinc Plated Steel & Mica Silver |

| Enclosure Pressure Gauge & Switch Diaphragms: | Fluorosilicone |

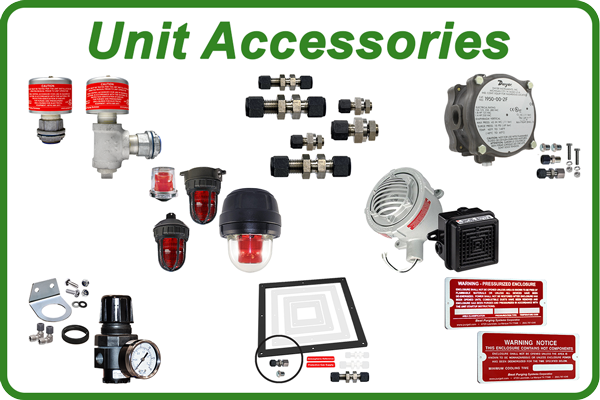

| Unit Accessories (Shipped loose with each Unit) | |

| Model EPWN Enclosure Pressure Warning Nameplate: | 0.10″ Velvet Lexan™ w/ VSB™ Adhesive |

| Fastener Kit Sealing Screws: | 316 Stainless Steel w/ Neoprene O-Ring |

| Fastener Kit Sealing Washers: | 18-8 Stainless Steel w/ Neoprene Washer |

| Fastener Kit Locking Nuts: | 316 Stainless Steel w/ Nylon Insert |

Velvet Lexan™ and VSB™ are Trademarks of

the 3M™ Company

Complete Information & Hardware are included with each Unit to make installation a fast and easy process!

Please visit our Technical Bulletins Page to review, print and share our Installation, Operation & Maintenance Manuals!

All Units are furnished with the following documentation and installation accessories:

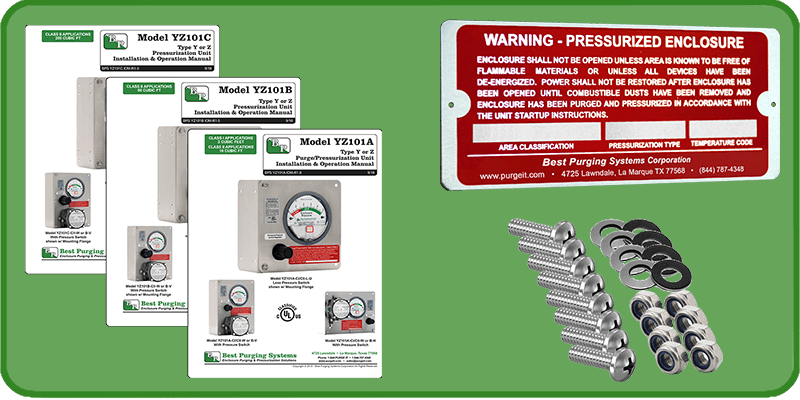

One (1) 14 Page Installation, Operation

& Maintenance Manual

One (1) Model EPWN Enclosure

Pressure Warning Nameplate

One (1) Set of Stainless Steel Unit

Mounting Fasteners

Additional Manuals & Warning Nameplates

are available with each Unit at time

of order placement, upon request.

Best Purging Systems Corporation provides a comprehensive 14 page full color Installation, Operation and Maintenance Manual with every Unit, along with a Model EPWN Enclosure Pressure Warning Nameplate and a complete set of stainless steel fasteners with neoprene sealing screws and washers. The Warning Label satisfies protected enclosure labeling requirements of NFPA 496, and is required on all doors and cover plates. The fastener kit provides sufficient fasteners to mount your Unit externally or in a panel mounted position (panel mounting applicable to universal configurations only). For additional Installation Operation and Maintenance Manuals, Enclosure Pressure Warning Nameplates or fasteners, please contact a Best Purging Systems Sales Associate!