Call (844) 787-4348

That's 844-PURGE-IT

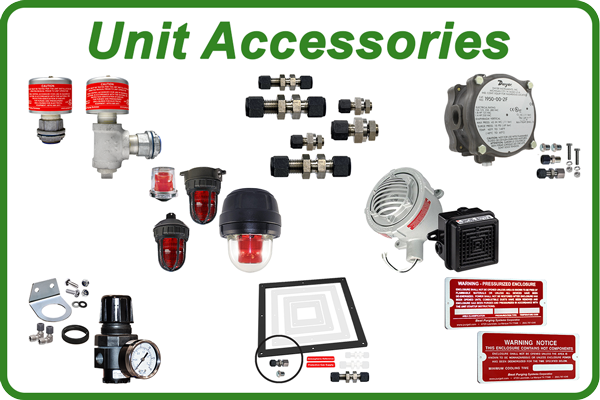

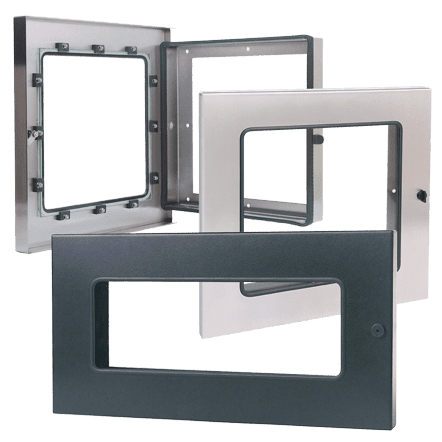

INSTRUMENT COVERS FOR PURGED ENCLOSURES

SIZING GUIDES & Specifications

Best Purging Systems Model PIAD Purgeable Instrument Access Doors are provided in several sizes and configurations to serve an extremely broad range of industrial and corrosive environment applications.

This section provides essential window size calculation and minimum clearance requirement guidelines and specifications for all hardware and gaset provided.

Please contact a Best Purging Sales Associate if any information is required to supplement the details presented below.

Click any item for more information, and click any image to enlarge…

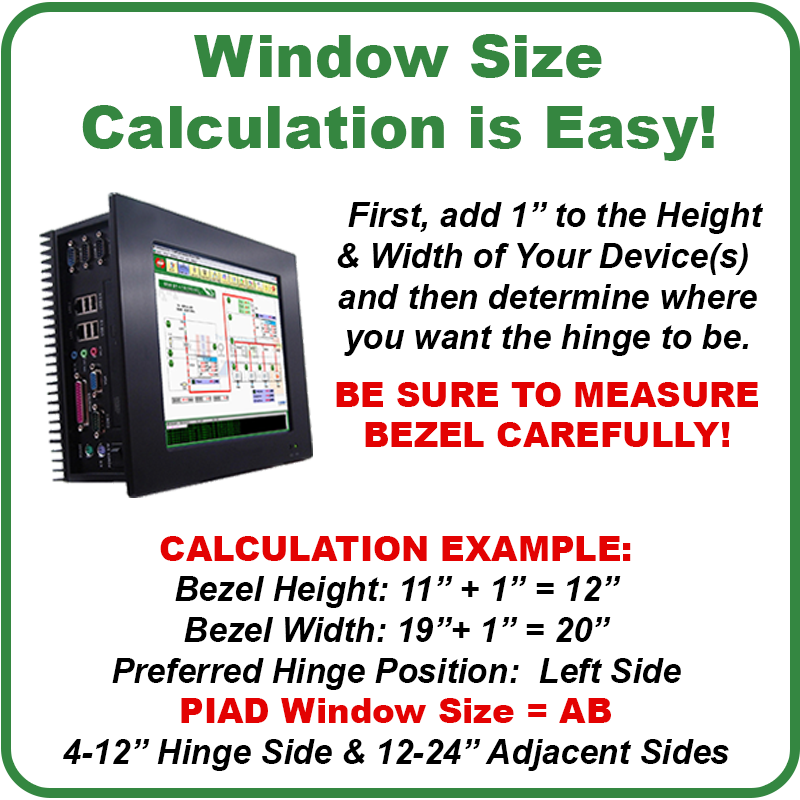

This diagram illustrates the best method for determining your PIAD Window Size.

Unless these recommendations are followed carefully, your Purgeable Instrument Access Door mounting frame may be too small to fit over the protected devices, and your viewing area may also be restricted!

Your PIAD Window Dimensions should be calculated by adding one-half inch (0.5″) to all sides of the protected device bezel, or 1” to the overall height and width of the device bezel or total area to be protected. This will ensure there will be no viewing obstructions and that the Purgeable Instrument Access Door’s mounting frame will fit easily around your protected device(s).

The next critical step of ensuring adequate clearance for all aspects of your Purgeable Instrument Access Door is presented below. Please study those recommendations very carefully to ensure you will get a PIAD that fits easily, does not interfere with other items around your PIAD and has sufficient clearance between the PIAD’s window and the devices you’re protecting!

Ensure your PIAD is properly ventilated in accordance with NFPA 496!

When your PIAD is utilized on purged or pressurized enclosures, it is critical to satisfy NFPA 496 Section 5.2.6 requirements regarding protection of compartments adjacent to the protected enclosure. We provide complementary technical assistance in this situation by helping you determine if the device(s) your PIAD is protecting will adequately ventilate the sealed area created by the PIAD.

If your devices do not provide adequate ventilation, we can recommend methods to 1) properly ventilate the sealed area within the PIAD (which NFPA 496 defines as an adjacent compartment); or 2) purge and/or pressurize the area created by the PIAD, either separately or in series with your protected enclosure, depending on the surrounding Area’s Classification.

Please contact our Sales Associates and Technical Consultants for more information, guidance and recommendations.

Mounting Clearance

Unless proper clearances are provided, a technician will have critical issues during installation!

After adding 1” to the bezel height and width dimensions of your protected device(s) to ensure your PIAD will fit easily around them and establish a window size, it’s also essential to add 10” to these same dimensions to ensure you’ll have adequate clearance around the outer sides of your PIAD, so it will not overlap or interfere with mounting other panel mounted devices adjacent to your PIAD.

Interior Clearance or Depth

The Standard Purgeable Instrument Access Door has an Interior Clearance of 2″

As another critical element of proper sizing, please note the standard depth of Best Purging Systems Instrument Access Doors, as measured from the surface of your protected enclosure to the rear side of the window is two inches (2″). This is adequate for most panel mounted devices, but if you need additional depth, please contact us to express your special interior clearance requirement!

At Best Purging Systems, we understand and appreciate the need to get it right the first time, so please feel free to contact a Sales Associate if you have any questions regarding clearance requirements.

| MATERIAL SPECIFICATIONS | |

| Latch Housing: | Black Polyester Powder Coated Die Cast Zinc or Electro-Polished 316L Grade Stainless |

| Latch Cam: | Case Hardened 1075 Steel |

| Latch Sleeve: | Dacrotized® Case Hardened 1065 Steel |

| Latch Shaft: | Dacrotized® Zinc Alloy Plated 12L14 Steel or 316 Grade Stainless |

| Latch Mounting Nut: | Dacrotized® Zinc Alloy Plated 12L14 Steel or Passivated 304 Grade Stainless |

| Retainer, Latch Jam Nuts, Latch & Pawl Lock Washers: | Zinc Plated 1010 Steel or Passivated 302 Grade Stainless |

| Latch Pawl: | Zinc Plated 1010 Steel or Passivated 304 Grade Stainless |

| Latch Pin: | Zinc Plated Case Hardened 1008 Steel |

| Latch Spring & Retainer: | Passivated 302 Grade Stainless |

| Latch O-Ring: | Buna-N Rubber, Black |

| Hand Operator Knob: | Black Polyester Powder Coated Die Cast Zinc or Electro-Polished 316L Grade Stainless |

| Tool Operator Latch Cap: | Black Polyester Powder Coated Die Cast Zinc or Electro-Polished 316L Grade Stainless |

| Key Operator Latch Cap: | Black Polyester Powder Coated Die Cast Zinc or Passivated 303 Grade Stainless |

| Key Operator: | Nickel Plated Steel |

Life-Time Guaranteed!

| MATERIAL SPECIFICATIONS | |

| Base Material: | Dense EPDM Rubber, 70 Shore A Durometer |

| Embedded Retainers: | Flexible Aluminum Wire or Stamped Steel |

| Bulb Material: | Custom Formulated EPDM Sponge Rubber, with Medium-Firm Density |

Best Purging Systems utilizes a high-quality replaceable door gasket to ensure a positive seal. The gasket is applied by pressure and the bottom portion features embedded aluminum wire or stamped steel clips to ensure strong retention, along with a series of gripping fingers that ensure a positive seal to the metal frame. The upper section is hollow to compress easily and retain its shape permanently, and features two raised ribs on its outer surface to seal completely along its entire length!

Best of all, it comes with a life-time guarantee – if it ever becomes worn, torn or damaged in any way, simply contact us. We’ll provide this gasket for free, and it’s easily replaced!

| MATERIAL SPECIFICATIONS | |

| Window Gasket: | Closed Cell Neoprene |

| Window Trim Molding: | Trim-Lok™ Extrusion Molded Neoprene |

| Window Retainer Clips: | Injection Molded 60 Durometer Santoprene™ |

| Retainer Fastening Hardware: | 316 Stainless Steel Locking Nut and Washer |

Best Purging Systems’ unique method of securing the PIAD window utilizes Trim-Lok™ Rubber Edge Trim and closed cell neoprene gasket placed between the Laminated or Wire Reinforced Safety Glass or Lexan™ Margard™ MR-10 window and the PIAD Door. The window is held in place with proprietary Santoprene™ clips and stainless steel hardware. This unique method of attachment secures the window in a suspended fashion, allowing damaged windows to be easily removed and replaced, without the need for special tools or sealant application!

Best Purging Systems offers a variety of materials for your PIAD Door and Mounting Frame, along with your Window that may be selected with a range of finishes at time of order.

These options are complemented by polished 316 grade stainless steel hinges, affixed to the door with stainless rivets and to the frame with stainless screws and cap nuts along with rubber sealing washers that permit easy Door detachment.

| MATERIAL SPECIFICATIONS | |

| Door & Mounting Frame Material Options: | 14 Gauge Carbon Steel, 14 Gauge 304 Grade Stainless Steel 14 Gauge 316 Grade Stainless Steel |

| Window Material Options: | 1/4″ Laminated Safety Glass, 1/4″ Lexan™ Margard™ MR-10 1/4″ Wire Reinforced Safety Glass |

| Removable Hinges: | High Gloss Finish 316 Stainless Steel |

| Flat Head Door Screws: | 8/32 316 Stainless Steel Hex Drive |

| Door Screw Retainers: | Zinc-Plated Steel Heavy-Duty Rivet Nuts w/ Open End, 8-32 Interior Thread |

| Flat Head Mounting Frame Screws: | 8/32 316 Stainless Steel Phillips Drive |

| Mounting Frame Washers: | .052″ Thick Rubber (blue) |

| Mounting Frame Cap Nuts: | 8/32 316 Stainless Steel |

Lexan and Margard are Trademarks of the Sabic Corporation

Dacrotized is a Registered Trademark of Metal Coatings International, Inc

Trim-Lok is a trademark of Trim-Lok, Incorporated

Santoprene is a trademark of the ExxonMobil Corporation

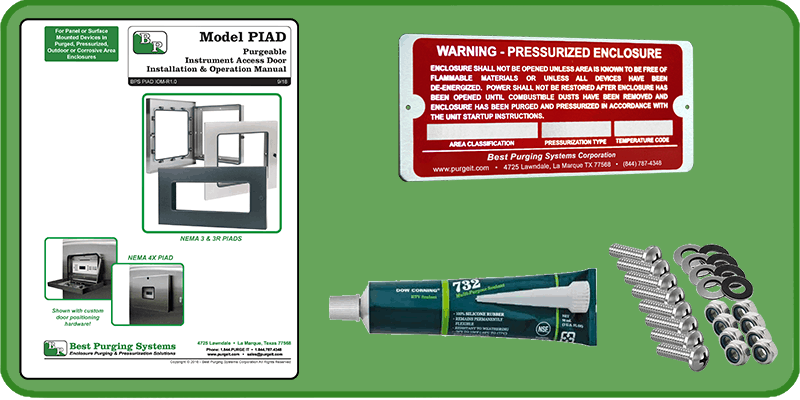

Complete Information & Hardware are included with each PIAD, to make installation a fast and easy process!

Please contact us to receive electronic copies of our Installation, Operation & Maintenance manuals for

your proposal!

All PIADS are furnished with the following documentation and installation accessories:

- One (1) 6 Page Installation, Operation & Maintenance Manual

- One (1) Model EPWN Enclosure Pressurization Warning Nameplate

- One (1) 3 Ounce Tube of Dow Corning 732 Silicone Sealant

- One (1) Set of Stainless Steel PIAD Frame Fasteners

Additional Manuals & Warning Nameplates are available with each PIAD at time of order

placement, upon request.

Best Purging Systems Corporation provides a comprehensive 6 page full color Installation, Operation and Maintenance Manual with every Purgeable Instrument Access Door, along with a Model EPWN Enclosure Pressure Warning Nameplate, a tube of silicone sealant and a complete set of stainless steel fasteners with neoprene sealing screws and washers. The Warning Label satisfies protected enclosure labeling requirements of NFPA 496, and is required on all doors and cover plates. The silicone sealant is provided to seal the frame of your Purgeable Instrument Access Door to your protected enclosure, and our Manual provides detailed instructions to ensure proper application and curing. The fastener kit provides sufficient fasteners to mount your Purgeable Instrument Access Door to the surface of your protected enclosure. For additional Enclosure Pressure Warning Nameplates, sealant or fasteners, please contact a Sales Associate!