Page 9 - F12-BPS-YZ102-Installation-Manual

P. 9

Purge Unit Operation

1. Ensure Protected Enclosure Power is OFF, Enclosure 7. Allow unit to purge protected enclosure for the required

Pressure Control Valve and Purge Control Valve are time marked on the Unit Start Up Instructions (5 minutes

closed, Protective Gas Supply is ON and alarm system minimum).

is activated (if utilized). Required Exchange Time/Enclosure Volume

2. Test the Purge Vent, Model PV-2, for proper operation.

Using the eraser end of a pencil or similar object, insert 4 Volumes 1 minute per 1.0 cf

test object from inside the enclosure to confirm vent 5 Volumes 1 minute per 0.8 cf

relief ball is operating properly. Note: For side mounted,

Model PV-2-S, remove plug from bottom of tee fitting to 8. Upon completion of the required purge time, close

test vent relief ball operation. the Purge Control Valve fully. The Enclosure Pressure

3. Close and Seal Protected Enclosure. Indicator will return to a “Safe” 0.25” w.c. reading.

4. Slowly turn the Enclosure Pressure Control Valve CCW 9. Confirm protected enclosure “Safe” pressure is stable.

until a “Safe” 0.25” reading is shown on the Enclosure Energize protected enclosure equipment.

Pressure Indicator. 10. Loss of “safe” pressure requires immediate attention.

5. Open the Purge Control Valve fully. The Enclosure Pressure Protected enclosure power should be deenergized if

Indicator will go off scale to the high side, this is normal. “Safe” pressure cannot be restored within a reasonable

6. Confirm a Min. 60 psi on Purge Injection Pressure Gauge. amount of time.

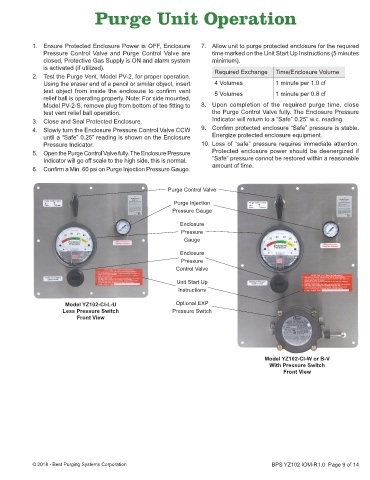

Purge Control Valve

Purge Injection

Pressure Gauge

Enclosure

Pressure

Gauge

Enclosure

Pressure

Control Valve

Unit Start Up

Instructions

Model YZ102-CI-L-U Optional EXP

Less Pressure Switch Pressure Switch

Front View

Model YZ102-CI-W or B-V

With Pressure Switch

Front View

© 2018 - Best Purging Systems Corporation BPS YZ102 IOM-R1.0 Page 9 of 14