Page 8 - F09-BPS-YZ101A-Installation-Manual

P. 8

Pressurization Unit & Switch Set Up

Pressurization Unit Set Up Pressure Switch Set Up

Class I installations require a 4 or 5 volume exchange through 1. The following directions are for purge models with the

the protected enclosure while maintaining a positive pressure. suffix -W or -B which are supplied with a flame proof

To determine unit flow rate, temporarily install a 0 - 10 scfh differential pressure switch (DPS).

flow meter between the unit and the protected enclosure.

Class II installations proceed to step 1. IMPORTANT NOTE

1. Ensure Protected Enclosure Power is OFF, Enclosure The differential pressure switch is intended solely for loss

Pressure Control Regulator is closed and Protective of safe pressure alarm and should not be used to control

Gas Supply is ON. power to the protected enclosure.

2. Adjust Redundant Regulator, if utilized, to 5 psi maximum

or skip to step 3 if enclosure is equipped with a Model 2. Connect alarm system wiring to the DPS via rigid

PV-2 Purge Vent. conduit and seal or other approved wiring method for

3. Test Purge Vent, if utilized. Using the eraser end of a the classified location.

pencil or similar object, insert from inside the enclosure 3. The DPS provides a Form C Dry NO, NC and C contact.

to confirm vent relief ball is operating properly. Note: Note: -B switches require 120 VAC or 24 VDC power to

Side mounted, Model PV-2-S, remove plug from bottom operate.

of tee fitting to test vent.

4. The alarm system should be connected in a fail safe

4. Close and Seal Protected Enclosure. configuration.

5. Slowly turn Enclosure Pressure Control Regulator

CW until a “Safe” 0.25” w.c. reading is shown on the

Enclosure Pressure Gauge. Note: If unable to achieve a

“ Safe” enclosure pressure, carefully check all enclosure

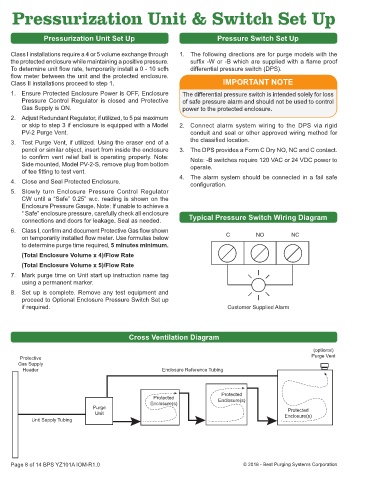

connections and doors for leakage. Seal as needed. Typical Pressure Switch Wiring Diagram

6. Class I, confirm and document Protective Gas flow shown C NO NC

on temporarily installed flow meter. Use formulas below

to determine purge time required, 5 minutes minimum.

(Total Enclosure Volume x 4)/Flow Rate

(Total Enclosure Volume x 5)/Flow Rate

7. Mark purge time on Unit start up instruction name tag

using a permanent marker.

8. Set up is complete. Remove any test equipment and

proceed to Optional Enclosure Pressure Switch Set up

if required. Customer Supplied Alarm

Cross Ventilation Diagram

(optional)

Protective Purge Vent

Gas Supply

Header Enclosure Reference Tubing

Protected

Protected Enclosure(s)

Enclosure(s)

Purge Protected

Unit Enclosure(s)

Unit Supply Tubing

Page 8 of 14 BPS YZ101A IOM-R1.0 © 2018 - Best Purging Systems Corporation