Page 2 - BPS-RR-Technical-Bulletin

P. 2

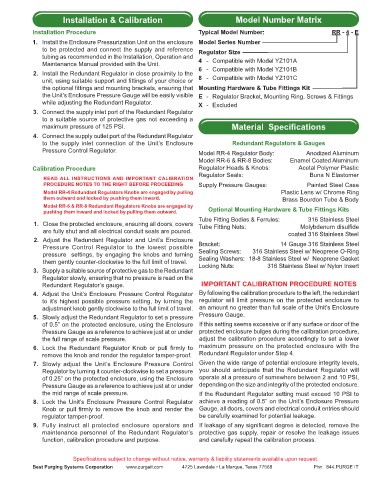

Installation & Calibration Model Number Matrix

Installation Procedure Typical Model Number: RR - 4 - E

1. Install the Enclosure Pressurization Unit on the enclosure Model Series Number

to be protected and connect the supply and reference Regulator Size

tubing as recommended in the Installation, Operation and

Maintenance Manual provided with the Unit. 4 - Compatible with Model YZ101A

2. Install the Redundant Regulator in close proximity to the 6 - Compatible with Model YZ101B

unit, using suitable support and fittings of your choice or 8 - Compatible with Model YZ101C

the optional fittings and mounting brackets, ensuring that Mounting Hardware & Tube Fittings Kit

the Unit’s Enclosure Pressure Gauge will be easily visible E - Regulator Bracket, Mounting Ring, Screws & Fittings

while adjusting the Redundant Regulator. X - Excluded

3. Connect the supply inlet port of the Redundant Regulator

to a suitable source of protective gas not exceeding a

maximum pressure of 125 PSI. Material Specifications

4. Connect the supply outlet port of the Redundant Regulator

to the supply inlet connection of the Unit’s Enclosure Redundant Regulators & Gauges

Pressure Control Regulator. Model RR-4 Regulator Body: Anodized Aluminum

Model RR-6 & RR-8 Bodies: Enamel Coated Aluminum

Calibration Procedure Regulator Heads & Knobs: Acetal Polymer Plastic

Regulator Seals: Buna N Elastomer

READ ALL INSTRUCTIONS AND IMPORTANT CALIBRATION

PROCEDURE NOTES TO THE RIGHT BEFORE PROCEEDING Supply Pressure Gauges: Painted Steel Case

Model RR-4 Redundant Regulators Knobs are engaged by pulling Plastic Lens w/ Chrome Ring

them outward and locked by pushing them inward. Brass Bourdon Tube & Body

Model RR-6 & RR-8 Redundant Regulators Knobs are engaged by

pushing them inward and locked by pulling them outward. Optional Mounting Hardware & Tube Fittings Kits

Tube Fitting Bodies & Ferrules: 316 Stainless Steel

1. Close the protected enclosure, ensuring all doors, covers Tube Fitting Nuts: Molybdenum disulfide

are fully shut and all electrical conduit seals are poured. coated 316 Stainless Steel

2. Adjust the Redundant Regulator and Unit’s Enclosure

Pressure Control Regulator to the lowest possible Bracket: 14 Gauge 316 Stainless Steel

pressure settings, by engaging the knobs and turning Sealing Screws: 316 Stainless Steel w/ Neoprene O-Ring

them gently counter-clockwise to the full limit of travel. Sealing Washers: 18-8 Stainless Steel w/ Neoprene Gasket

316 Stainless Steel w/ Nylon Insert

Locking Nuts:

3. Supply a suitable source of protective gas to the Redundant

Regulator slowly, ensuring that no pressure is read on the

Redundant Regulator’s gauge. IMPORTANT CALIBRATION PROCEDURE NOTES

4. Adjust the Unit’s Enclosure Pressure Control Regulator By following the calibration procedure to the left, the redundant

to it’s highest possible pressure setting, by turning the regulator will limit pressure on the protected enclosure to

adjustment knob gently clockwise to the full limit of travel. an amount no greater than full scale of the Unit’s Enclosure

5. Slowly adjust the Redundant Regulator to set a pressure Pressure Gauge.

of 0.5” on the protected enclosure, using the Enclosure If this setting seems excessive or if any surface or door of the

Pressure Gauge as a reference to achieve just at or under protected enclosure bulges during the calibration procedure,

the full range of scale pressure. adjust the calibration procedure accordingly to set a lower

6. Lock the Redundant Regulator Knob or pull firmly to maximum pressure on the protected enclosure with the

remove the knob and render the regulator tamper-proof. Redundant Regulator under Step 4.

7. Slowly adjust the Unit’s Enclosure Pressure Control Given the wide range of potential enclosure integrity levels,

Regulator by turning it counter-clockwise to set a pressure you should anticipate that the Redundant Regulator will

of 0.25” on the protected enclosure, using the Enclosure operate at a pressure of somewhere between 2 and 10 PSI,

Pressure Gauge as a reference to achieve just at or under depending on the size and integrity of the protected enclosure.

the mid range of scale pressure. If the Redundant Regulator setting must exceed 10 PSI to

8. Lock the Unit’s Enclosure Pressure Control Regulator achieve a reading of 0.5” on the Unit’s Enclosure Pressure

Knob or pull firmly to remove the knob and render the Gauge, all doors, covers and electrical conduit entries should

regulator tamper-proof. be carefully examined for potential leakage.

9. Fully instruct all protected enclosure operators and If leakage of any significant degree is detected, remove the

maintenance personnel of the Redundant Regulator’s protective gas supply, repair or resolve the leakage issues

function, calibration procedure and purpose. and carefully repeat the calibration process.

Specifications subject to change without notice, warranty & liability statements available upon request.

Best Purging Systems Corporation www.purgeit.com 4725 Lawndale • La Marque, Texas 77568 Phn: 844.PURGE IT